Takes you on a journey through the complicated world of metalworking. It is your complete guide to understanding one of the most fundamental processes used in manufacturing and building. This blog post aims to explain the complicated and exciting process of turning raw metal into flat, helpful sheets used in many situations, from the sleek outsides of cars to the firm outsides of buildings.

We'll look at the tools, techniques, and technologies that make this vital manufacturing method possible, using a mix of scientific information and easy-to-understand explanations. This post will teach and excite you, whether you're an experienced engineer, a new maker, or just interested in metal fabrication. Step by step, we'll show you the art and science behind rolling sheet metal. Come along for the ride.

How To Start With Sheet Metal

Equip Yourself With The Right Tools

The right tools are your best allies in sheet metal fabrication. Begin with essential hand tools like metal shears, hammers, and punches. Invest in more sophisticated equipment like brakes, rollers, and welding machines as you progress. Remember, safety gear is non-negotiable; always wear gloves, goggles, and ear protection.

Learn Basic Techniques

Sheet metal fabrication involves several vital techniques, including cutting, bending, and joining. Start by learning to measure and cut sheet metal accurately. Practice bending metal to desired angles using a bench vice or a brake. Joining pieces together through techniques like riveting, welding, or adhesives is also crucial. Each project will require a different combination of these techniques, so familiarity and practice are vital.

Start Simple

Begin your journey with simple projects. Websites like Instructables offer beginner-friendly sheet metal projects that provide a hands-on way to apply basic techniques. Projects like making a simple box, a birdhouse, or a planter can teach you the fundamentals of cutting, bending, and joining metal without overwhelming you.

Understanding The Business Side

If your interest in sheet metal goes beyond hobbyist projects and you're considering starting an industrial sheet metal work business, it's crucial to grasp both the craft and the commerce. Conduct thorough market research to understand your area's demand for sheet metal products. Craft a detailed business plan that covers your business model, market analysis, and financial projections. Start by focusing on a niche within the sheet metal industry—this can provide a clear direction and reduce competition.

Embrace Technology And Software

Leveraging technology can significantly enhance your sheet metal projects or business. Learning software like SOLIDWORKS for sheet metal design can be incredibly beneficial for those inclined towards engineering or detailed design work. It offers tools specifically for designing and unfolding sheet metal parts, allowing you to visualize and prototype designs before cutting your first piece.

Continuous Learning And Improvement

The field of sheet metal fabrication is vast and constantly evolving. Whether through online tutorials, community college courses, or workshops, continuing to learn about new materials, tools, and technologies will keep your skills sharp and your projects innovative. Staying updated on industry trends and technology can provide a competitive edge for business owners.

Overview Of The Metal Rolling Process

The essence of this method is not just altering the shape but enhancing the properties of the metal to meet specific manufacturing requirements. This overview seeks to unravel the layers of the metal rolling process, shedding light on its principles, applications, and technological advancements that have shaped its evolution.

The Basics Of Metal Rolling

At its core, metal rolling is a metalworking process that reduces the thickness of a metal piece and increases its length. This deformation process is achieved under compressive forces exerted by rotating rolls, fundamentally transforming the metal's cross-sectional area.

The operation can be performed at various temperatures, leading to two primary categories: hot and cold rolling. Hot rolling is conducted above the metal's recrystallization temperature, offering reduced deformation resistance. In contrast, cold rolling occurs at or near room temperature, resulting in a higher-quality finish and more precise dimensions.

Types Of Metal Rolling Processes

The diversity of rolling processes allows for a wide range of metal shapes and sizes. These include flat rolling, where the final product is a flat sheet; shape rolling, which creates specific profiles; and ring rolling, which produces seamless rings. Each method has unique equipment and technology tailored to achieve the desired characteristics of the finished product.

Technological Advancements In Metal Rolling

The field of metal rolling has witnessed significant technological advancements to improve efficiency, precision, and material properties. Automation and control systems have become integral, enabling precise adjustments to rolling parameters and ensuring consistent quality. Additionally, developments in materials science have allowed for the rolling of a broader spectrum of materials, including those with complex microstructures.

Applications And Implications

Metal rolling has vast and varied applications, finding utility in every corner of the industrial world. Rolled products are omnipresent, from the steel beams that frame our buildings to the aluminium foils that wrap our food. Beyond its immediate applications, the metal rolling process is pivotal in advancing sustainability within the manufacturing sector. Improving material properties and production efficiency contributes to developing lighter, more robust, and more durable products.

The Future Of Metal Rolling

As we look to the future, the metal rolling process continues to evolve, driven by ongoing research and innovation. Emerging technologies promise even greater efficiencies, the potential for rolling more challenging materials, and further reductions in environmental impact. The continuous refinement of rolling techniques and equipment opens new horizons for the application of rolled products, underscoring the enduring importance of this foundational manufacturing process.

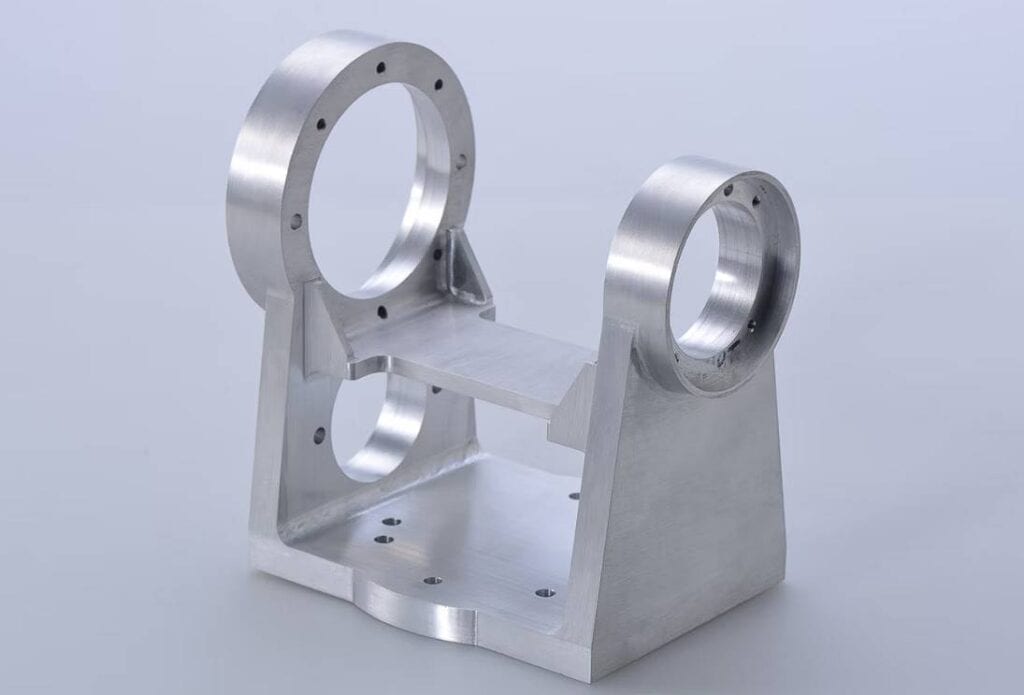

Machinery And Equipment Used In Rolling Sheet Metal

Drawing on my existing knowledge base, I can provide a general overview and insight into the types of equipment commonly used in sheet metal fabrication and the role of sheet metal rolling equipment. If you're looking for specific information from those links, I can help guide you on interpreting or summarising that type of content based on general principles.

Equipment For Sheet Metal Fabrication

Sheet metal fabrication is a comprehensive process involving cutting, bending, and assembling metal to create various products and components. The equipment used in sheet metal fabrication can be broadly categorized based on these processes:

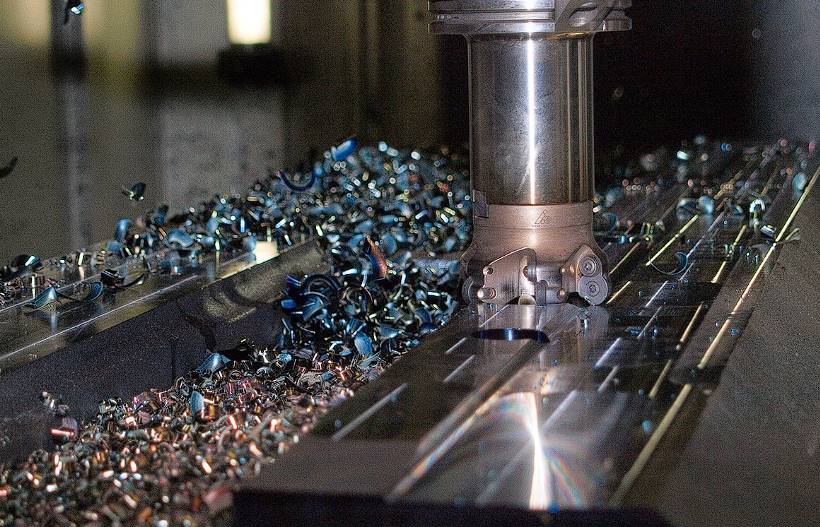

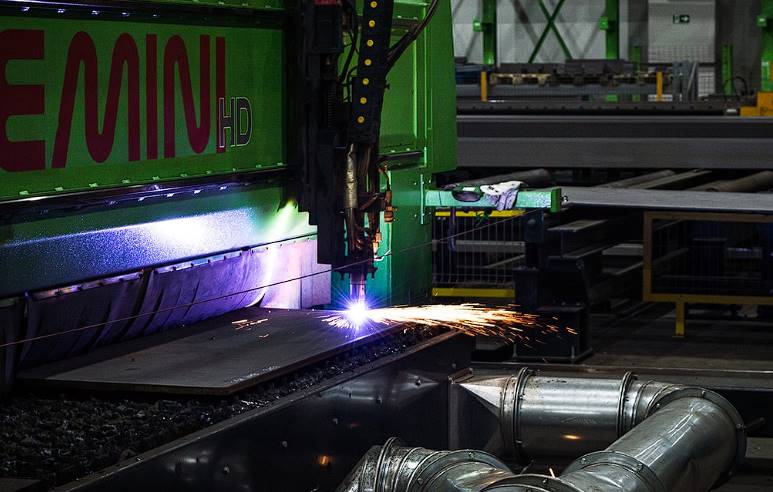

Cutting Equipment

- Laser Cutters: Utilize high-powered lasers to make precise cuts in metal. Ideal for intricate designs.

- Plasma Cutters: Employ a high-velocity jet of ionized gas to cut through metal. It is best for thicker materials.

- Waterjet Cutters: Use a high-pressure stream of water, often mixed with an abrasive material, to cut metal without altering its intrinsic properties.

Bending Equipment

- Press Brakes: Apply force to bend metal sheets at desired angles. They come in mechanical, pneumatic, hydraulic, and electric varieties.

- Folding Machines: Also known as panel benders, these machines clamp the sheet metal in place and then fold it to the required angle using a swinging beam.

Joining Equipment

- Welding Machines: Join metal parts using various welding techniques, such as MIG, TIG, and stick welding.

- Riveting Machines: Use rivets to join pieces of metal, offering a robust alternative to welding in some applications.

Finishing Equipment

- Grinders and Sanders: Remove burrs, sharp edges, and improve the surface finish of the metal parts.

- Polishing Machines: Enhance the aesthetic appearance of metal surfaces to a mirror-like finish.

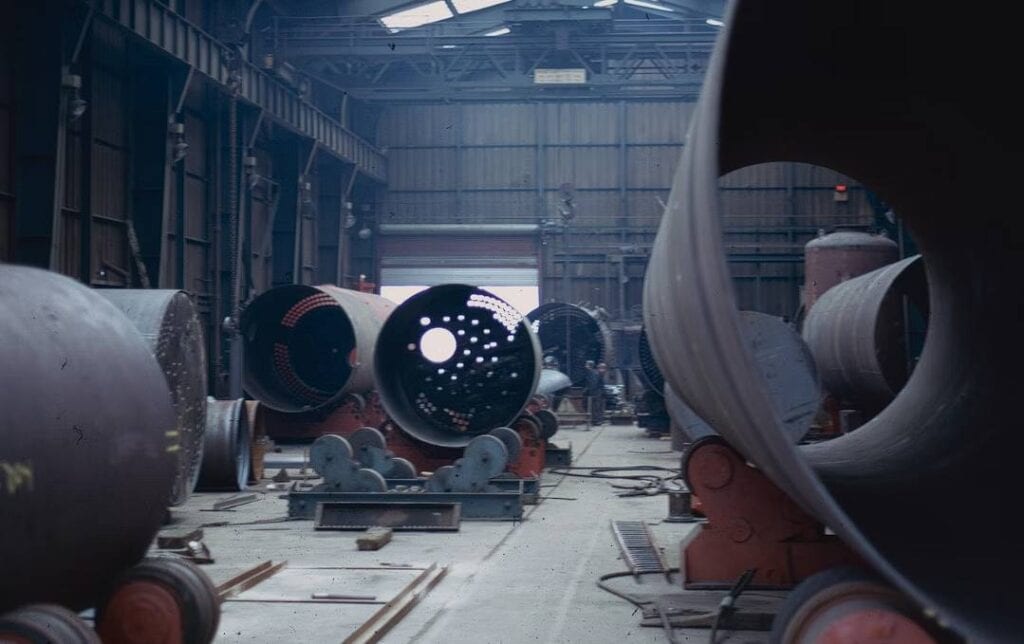

Sheet Metal Rolling Equipment

Sheet metal rolling equipment is crucial for shaping and curving metal sheets, rods, and other profiles. Here are some common types:

Two-High Rolling Mills

- It consists of two opposing rolls between which the metal sheet is passed. The rolls can be reversible or non-reversible.

Three-High Rolling Mills

- Feature three rolls in a vertical arrangement, allowing for continuous operation by passing the workpiece through the top and bottom rolls in one direction and then through the middle and bottom rolls in the reverse direction.

Four-High Rolling Mills

- Utilize two smaller work rolls supported by two larger backup rolls. This setup is designed for precision rolling of thin and high-strength materials.

Cluster Mills

- They are known for multiple backing rolls on each side of the work rolls, allowing for the rolling of fragile materials or materials requiring high precision.

Tandem Rolling Mills

- It consists of several rolling stands in a row, allowing for the sequential reduction of metal thickness. This configuration mass-produces flat products, such as sheets and strips.

The Step-By-Step Process Of Rolling Sheet Metal

Rolling sheet metal transforms flat metal sheets into various shapes and sizes, crucial for countless manufacturing applications. This operation requires precision and control and unfolds through several stages to ensure the final product meets the desired specifications. Here's a detailed look at each step involved in rolling sheet metal.

Material Selection

- Initial Assessment: The process begins with selecting the appropriate type of metal based on the final product's required characteristics, such as strength, flexibility, and corrosion resistance.

Preparing The Metal

- Heating (for Hot Rolling): If the process involves hot rolling, the metal is preheated to a specific temperature above its recrystallization point, making it more malleable and more accessible to shape.

- Cleaning and Lubricating (for Cold Rolling): In cold rolling, the metal sheet is cleaned to remove any impurities and lubricated to reduce friction during the rolling process.

The Rolling Operation

- Passing Through Rolls: The prepared metal sheet is then passed through one or more sets of rolls. These rolls compress the metal, reducing its thickness and altering its shape per the requirements.

- Adjusting the Rolls: The gap between the rolls is precisely adjusted to control the thickness and shape of the final product. This may involve multiple passes through the rolls with incremental adjustments.

Monitoring And Controlling

- Process Control: Throughout the rolling process, various parameters such as roll speed, pressure, and temperature (in hot rolling) are closely monitored and adjusted to ensure uniformity and quality of the product.

- Quality Checks: The metal is periodically inspected for thickness, surface finish, and other quality parameters to ensure it meets the specified standards.

Post-Rolling Operations

- Cooling: After rolling, the metal is allowed to cool down gradually. This is essential in hot rolling to achieve the desired mechanical properties and relieve internal stresses.

- Cutting and Trimming: The rolled metal may be cut or trimmed to the desired dimensions and shapes.

- Further Processing: Additional processes such as annealing, coating, or painting might be applied to enhance the metal's properties or appearance.

Finishing Touches

- Final Inspection: A final inspection ensures the product meets all specifications and quality standards.

- Packaging and Dispatch: The finished rolled metal is packaged appropriately for storage or immediate dispatch to the customer or the next manufacturing phase.

Conclusion

Sheet metal rolling is a crucial process in manufacturing and building. It turns raw metal into flat sheets used in various applications. It involves several key techniques, such as cutting, bending, and joining. To start, equip yourself with the right tools, such as metal shears, hammers, and punches, and learn basic techniques like cutting, bending, and joining. Start simple by starting with beginner-friendly projects on websites like Instructables.

Continuous learning and improvement are essential for maintaining skills and project innovation. The metal rolling process is vast and constantly evolving, with various types of rolling processes, such as flat rolling, shape rolling, and ring rolling, each with unique equipment and technology. Technological advancements have improved efficiency, precision, and material properties, with automation and control systems enabling precise adjustments to rolling parameters.

Metal rolling has various applications in various industries, from steel beams to aluminium foils. It also plays a pivotal role in advancing sustainability within the manufacturing sector by improving material properties and production efficiency, contributing to the development of lighter, more robust, and more durable products.

The metal rolling process is evolving due to ongoing research and innovation. It offers greater efficiencies, the potential for rolling more challenging materials, and reduced environmental impact. Standard equipment used in sheet metal fabrication includes laser cutters, plasma cutters, waterjet cutters, pressing brakes, folding machines, welding machines, riveting machines, finishing equipment like grinders and Sanders, and polishing machines.

The step-by-step process of rolling sheet metal involves selecting the appropriate metal, preheating it for hot rolling, cleaning and lubricating it for cold rolling, passing through rolls, and adjusting the rolls. Process control is crucial throughout the rolling process, with parameters such as roll speed, pressure, and temperature closely monitored and adjusted. Quality checks are conducted to ensure the product meets specified standards.

Post-rolling operations include cooling, cutting and trimming, further processing, and final inspection. Final inspection ensures the product meets all specifications and quality standards. The finished rolled metal is packaged appropriately for storage or immediate dispatch to the customer or the next manufacturing phase. The evolution of the metal rolling process highlights its importance in the future of manufacturing.

Content Summary

- The blog post embarks on a journey through the world of metalworking, focusing on sheet metal rolling.

- It aims to demystify transforming raw metal into versatile, flat sheets.

- Sheet metal is integral to various industries, including automotive and construction.

- The post combines scientific information and accessible explanations to educate readers.

- Readers from various backgrounds, including engineering and hobbyist making, will find the content informative and exciting.

- The step-by-step demonstration highlights the art and science behind rolling sheet metal.

- Proper tool selection is crucial in sheet metal fabrication, starting with essential hand tools and advancing to more sophisticated equipment.

- Safety gear, such as gloves, goggles, and ear protection, is essential.

- Sheet metal fabrication involves fundamental techniques like cutting, bending, and joining.

- Simple projects can provide hands-on experience with basic fabrication techniques.

- Understanding sheet metal's craft and commerce is essential for those looking to start a business.

- Market research and a detailed business plan are crucial for starting a sheet metal work business.

- Continuous learning and improvement are vital in the evolving field of sheet metal fabrication.

- The blog overviews the metal rolling process and its importance in manufacturing.

- Metal rolling reduces the thickness of metal pieces and increases their length.

- The process is categorised into hot and cold rolling, each with distinct benefits.

- Various metal shapes and sizes can be achieved through different rolling processes.

- Technological advancements have improved efficiency, precision, and the range of materials that can be rolled.

- Metal rolling has a wide array of applications across different industries.

- The future of metal rolling looks promising, with ongoing research and innovation.

- Machinery and equipment used in rolling sheet metal vary based on the specific process.

- Cutting equipment like laser, plasma, and waterjet cutters play a crucial role in sheet metal fabrication.

- Bending equipment includes press brakes and folding machines for shaping metal.

- Joining techniques involve welding and riveting to assemble metal pieces.

- Finishing equipment like grinders, sanders, and polishing machines enhance the surface quality of metal products.

- Two high-rolling mills consist of two opposing rolls for sheet metal passing.

- Three-high rolling mills allow for continuous operation without reversing the roll's direction.

- Four-high rolling mills are designed for the precision rolling of thin materials.

- Cluster mills support very thin or high-precision material rolling.

- Tandem rolling mills are used to mass-produce flat products like sheets and strips.

- The rolling of sheet metal begins with selecting the appropriate type of metal.

- In hot rolling, metal is preheated to become more malleable.

- Cold rolling involves cleaning and lubricating the metal sheet for a smoother process.

- Adjusting the rolls is crucial for controlling the thickness and shape of the metal.

- Various parameters, such as roll speed, pressure, and temperature, are closely monitored.

- Quality checks ensure the metal meets specified standards.

- Post-rolling operations include cooling, cutting, trimming, and further processing.

- A final inspection guarantees the product's quality before packaging and dispatch.

- This comprehensive overview aims to provide a thorough understanding of sheet metal rolling.

- The post underscores the significance of sheet metal in manufacturing and its impact on modern infrastructure.

- Readers are encouraged to explore the fascinating world of metal fabrication through this informative guide.

- The blend of detailed explanations and practical insights aims to engage a broad audience.

- The importance of continual learning and adapting to new technologies is highlighted.

- The metal rolling process is presented as both an art and a science, requiring skill and precision.

- The evolution of metal rolling techniques reflects the advancements in manufacturing technology.

- The post emphasizes the role of metal rolling in achieving sustainability in manufacturing.

- Emerging technologies in metal rolling promise further to enhance the efficiency and capabilities of this process.

- The narrative style aims to make the complex topic of metal rolling accessible and engaging.

- Overall, the blog post offers a rich and detailed exploration of the process of rolling sheet metal, combining technical depth with reader-friendly explanations.

Frequently Asked Questions

Yes, rolling can significantly affect the metal's properties. Hot rolling generally enhances flexibility, while cold rolling improves tensile strength and hardness. The process can also influence the metal's grain structure, impacting its performance.

The primary equipment used is a rolling mill, which can vary in design to accommodate different metals and rolling processes. Common types include two-high, three-high, four-high, cluster mills (or Sendzimir mills), and tandem rolling mills.

Quality is ensured through precise control of the rolling process parameters, including roll speed, pressure, and temperature in hot rolling. Post-rolling inspections for thickness, surface finish, and material properties are also crucial.

Limitations may include the initial cost of rolling mill machinery, the need for skilled operation, and the potential for defects if the process parameters must be appropriately managed. The choice of rolling process (hot vs. cold) also presents trade-offs regarding material properties and surface finish.

Recent innovations include developing more sophisticated control systems for improved precision, introducing new materials capable of withstanding extreme conditions, and advancements in automation to enhance efficiency and reduce labour costs.