Is learning about Metal Inert Gas (MIG) welding something that interests you? In this post, we'll learn all about MIG welding and see why it's so widely used in the welding industry. Everything from the basic technique and equipment to the applications and benefits of MIG welding will be covered in depth. So let's dive in and learn everything we can about MIG welding!

What Is MIG Welding?

One welding method that employs electricity to melt and combine metal components is metal inert gas welding (MIG welding). MIG welding's popularity has skyrocketed since its inception in the early twentieth century thanks to its speed and ease of usage. Keep reading to find out...

Gas metal arc welding (GMAW) has been used since 1948, and MIG welding is a subset of this technique. This technique has been called gas metal arc welding, flux-cored arc welding, short-circuit welding, and spray arc welding, but the basics are the same.

How Does the MIG Welding Process Work?

Before beginning the MIG welding technique, you should review the meanings of a few specialised phrases that will come up frequently.

To become proficient at MIG welding, one must first learn the fundamentals.

What are the Characteristics that Can Be Found in a Weld

Metal Parent

The metal being welded together is known as the parent metal.

Metal Filler

This is the metal used to forge the connections between the other metals.

Weld Metal

All molten and retained metal from weld production is considered weld metal.

Heat Affected Zone

That portion of the parent metal that is metallurgically altered by the welding heat but does not melt is called the Heat Affected Zone (HAZ).

Fusion Line

Weld metal and the HAZ split apart at the fusion line. This is an unconventional term for the weld joint.

Weld Zone

The weld zone consists of the weld metal and the HAZ.

Gun/MIG Welding Unit

Gas Metal Arc welding, often known as MIG welding, requires a special welding gun.

The control switch, contact tip, power cable, gas hose, gas nozzle, power, electrode conduit, and shielding gas flow are some of the many parts of a MIG welding gun.

The copper contact tip is sometimes subjected to chemical treatment. This lessens the amount of spatter created while welding.

Electrical energy is delivered from the power source to the electrode through the power cord and contact tip. The amount of metal that comes into contact with the electrode depends on the size of the contact tip.

The electrode liner and conduit guide and protect the electrode wire. This prevents the wires from buckling and ensures that electricity continues to flow unimpeded.

The shielding gas is distributed uniformly across the welding area by the gas nozzle. Therefore, the inconsistent gas flow will compromise the safety of the welding area.

A bigger gas nozzle provides a more effective shielding effect when more molten weld pool results from high-current activities. In addition, after very hot operations, water from the gun's hose can cool down the welding equipment.

The Methods and Procedures Involved in MIG Welding

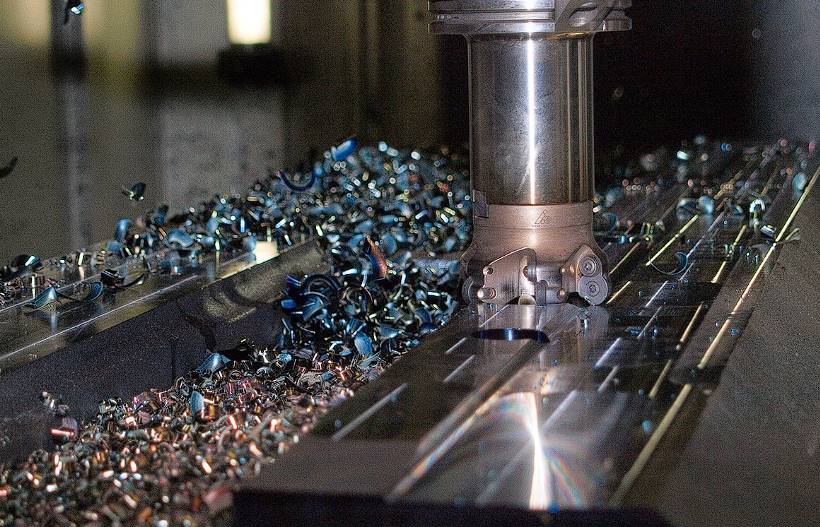

MIG welding, which employs a wire electrode, is called "wire welding."

The electrode in welding equipment is a thin wire fed continuously from a reel. Both a cored and a solid wire feed are available.

Solid wires are wires without extraneous components, while cored wires are composites built out of a metal casing filled with another metal or flux powder.

When the trigger is depressed on a welding machine, an arc is created between the electrode wire and the joined material. An arc weld creates a weld pool by melting the wire and the workpiece.

In MIG welding, the wire is used for not one but two purposes. "wire welding" refers to using a metal wire as both a heat source and a filler metal in a weld.

A copper contact tube consistently introduces electricity into the wire.

When MIG welding, the shielding gas protects the substance used as a filler and the finished product from atmospheric contact.

A nozzle introduces The shielding gas into the area around the wire. When settling on a shielding gas, the welded material and intended use are two considerations.

MIG welding is semi-automatic since an external power source manages the wire feed rate and arc length. Still, the welder manages the welding speed and wire location.

Polarity and Voltage

MIG welding requires a positively charged wire connected to a constant voltage source.

Since DC power is used during MIG welding, the current travels in the opposite direction of a car battery.

This also applies to polarity. When using a MIG welder with a positive D/C electrode, the control knob must be connected to the circuit's positive terminal.

MIG welding uses a current that flows away from the base metal and into the tool's grip.

A constant voltage power supply is what's needed for MIG welding. Adjusting and controlling the welding current.

Methods of Metal Conversion

Metal can be transported from the wire electrode to the weld pool in four ways.

- Short-Circuiting Mode

- Pulsed Mode

- Spray Mode

- Globular Mode

Short-Circuiting Mode

The short-circuiting mode, called the Dip Mode, is characterised by frequent electrical short-circuits, ultimately leading to an electrode synthesis by metal-cored or solid-wire deposition.

Metals may be moved with minimal energy expenditure.

Contact between the electrode and the pool of molten metal or the base material is required for metal transfer.

All orientations, including upside-down, bottom-up, sideways, flat, and above, are possible with the short-circuiting mode of metal transfer.

It is better suited for pipe applications, is easier to use, has an electrode efficacy of 93% or higher, accepts a less-than-ideal fit, and offers a mode with less heat input that shortens the welding distortion.

Globular Mode

Metal is deposited. Metal transfer occurs in a spherical mode in short circuits and massive, gravity-assisted drops from constant metal or metal wire electrodes fed into the device.

The shape of the huge drops is not uniform. Instead, it's a changeover between the short-circuiting phase and the globular transfer phase, which starts when the former phase concludes.

In this process, the electrode does not touch the foundation.

Making welds at extremely high rates, using cheap Co2 gas as a shielding gas, and using cheap metal-cored or solid electrodes are just a few benefits of the rounded metal transfer method.

Spray Mode

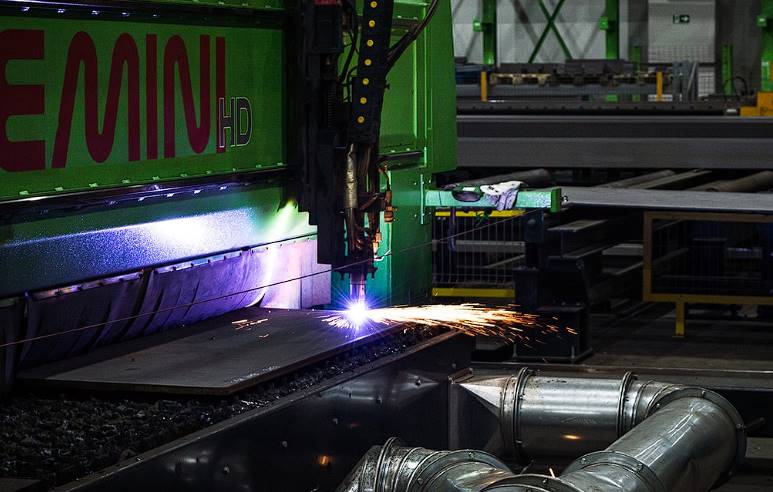

Spray deposition is a continuous process where metal is deposited at relatively high energies from a cored or solid-wired electrode.

Unlike the rounded transfer method, which results in irregularly shaped droplets, this one creates a steady stream of small molten metal droplets.

The spray mode has many advantages, including high disposition rates, no weld spatter, flexibility in post-weld cleaning and heavy-duty automation, robotics, and semi-automation. It also has a high electrode efficiency of up to 98%, great ease of use, and an excellent weld bead appearance.

Pulsed Mode

This technique is an extremely refined form of the spray mode. Welding is performed at both low and high amounts of current.

When the current is strong, a single droplet of molten metal is transferred.

The pulsed mode has the most to offer when comparing the benefits of different types that occur during metal-in-gas welding.

This method is becoming more popular due to its low spatter, high resistance, lack of fusion defects, excellent weld beads, popularity amongst operators, low heat-induced distortion, misaligned welding capability, 98 per cent effectiveness of electrodes, and suitability for Uses for Robots and Automation.

Shielding Gases

As was explained earlier in this piece, shielding gases are used in MIG welding to prevent a pool of molten weld metal reacting with atmospheric elemental oxygen and a few other things.

However, protective gases have other purposes as well.

The presence of shielding gases drastically affects metal transmission and arc stability.

It also serves other purposes, such as:

- Arc plasma nucleation

- Arc root stabilisation at the work surface guarantees a continuous flow of molten metal from the weld pool wiring.

The penetration of the weld, the weld's mechanical properties, and the nature of the welding arc are all affected by the gas used in MIG welding.

Argon, oxygen, carbon dioxide, and a specific blend of gases containing helium are some of the most frequent gases used for protection in MIG welding.

When welding dissimilar metals, the shielding gases must be adjusted accordingly. Common gases used for welding steels include carbon dioxide and argon. In addition, argon and helium-argon mixtures are frequently used for non-ferrous metals.

Use of the MIG Welding Method

MIG welding is a flexible method used on thick and thin sections. Welding involves melting the surface of the base materials cools to form a weld pool and a strong link between the metals.

Welding is performed by continually introducing shielding gas and a disposable heated wire electrode into a welding torch. The electrode wire is positively charged and then linked to a power source that provides a steady voltage to activate the welding process. Constant current systems and alternating current systems are also viable options.

The welding begins when the wire electrode contacts the parts to be joined. An electric arc is created when the metal touches the electrode. Next, a weld pool is formed when the intense heat of an electric arc melts the surface of the metal and the wire electrode. As the molten weld pool cools, it solidifies into a permanent weld. Next, shielding gas is injected alongside the electrode from the welding torch nozzle to keep the molten weld pool dry and impurities-free. When choosing a shielding gas, consider the metal being welded and its intended use. The welder moves the welding flame down the joint line as the welding progresses.

The core of the wire electrode may or may not be present, and its diameter can range from 0.6 mm to 1.6 mm. The electric arc at the contact point provides heat and filler metal for the weld. The wire is a disposable electrode since it melts when heated and is used in welding. The wire electrode receives its welding current from the torch's contact tip.

The power source determines wire feeding speed and arc length in semi-automatic MIG/MAG welding. However, the welder must manually adjust the wire's location and movement speed. Automatic MIG/MAG welding is performed entirely without human involvement.

Benefits of MIG Welding

- Due to the wire being continually fed, MIG welding is very efficient.

- MIG welding is faster and more efficient than TIG (Tungsten Inert Gas) and SMAW (Shielded Metal Arc Welding).

- Copper, aluminium, nickel, and iron are just some of the many metals and alloys easily welded using the flexible MIG welding method.

- Dissimilar metals can be joined using this method.

- The shielding gas safeguards the electric arc, transferring the metal across it. Therefore, only some of the alloying components are lost.

- Weld spatter is minimal and straightforward to clean up after using this procedure.

Some Disadvantages of MIG Welding

- MIG welding is unsuitable for overhead or vertical welding due to the weld puddle's high heat input and fluidity.

- The machinery used for MIG welding is more complicated than that used for shielded metal-arc welding.

Conclusion

MIG welding is a welding method that employs electricity to melt and combine metal components. It has been popular since its inception in the early twentieth century due to its speed and ease of usage. MIG welding requires a special welding gun with a control switch, contact tip, power cable, gas hose, gas nozzle, power, electrode conduit, and shielding gas flow. The weld metal parent is the metal being welded together, the metal filler is the metal used to forge the connections between the other metals, the weld metal is all molten and retained metal from weld production, the heat affected zone is the portion of the parent metal that is metallurgically altered by the welding heat but does not melt, and the fusion line is the weld metal and the HAZ split apart at the fusion line. MIG welding is a semi-automatic process that uses a wire electrode as both a heat source and a filler metal in a weld.

The electrode liner and conduit guide and protect the wire, while the shielding gas is distributed uniformly across the welding area by the gas nozzle. MIG welding is semi-automatic since an external power source manages the wire feed rate and arc length, while the welder manages the welding speed and wire location. MIG welding requires a positively charged wire connected to a constant voltage source, and the current travels in the opposite direction of a car battery. Metal conversion methods are used to adjust and control the welding current. Metal can be transported from the wire electrode to the weld pool in four ways: Short-Circuiting Mode, Pulsed Mode, Spray Mode, and Globular Mode.

The Dip Mode is characterised by frequent electrical short-circuits and metal-cored or solid-wire deposition, while the Globular Mode is deposited in a spherical mode. Spray Mode is a continuous process where metal is deposited at relatively high energies from a cored or solid-wire electrode. Pulsed Mode is an extremely refined form of the spray mode, and is becoming more popular due to its low spatter, high resistance, lack of fusion defects, excellent weld beads, popularity amongst operators, low heat-induced distortion, misaligned welding capability, 98% effectiveness of electrodes, and suitability for Uses for Robots and Automation. Shielding gases are used in MIG welding to prevent a pool of molten weld metal reacting with atmospheric elemental oxygen. They also serve other purposes, such as arc plasma nucleation, arc root stabilisation, and penetration of the weld.

Common gases used for welding steels include carbon dioxide and argon, and argon and helium-argon mixtures are commonly used for non-ferrous metals. Welding is performed by continually introducing shielding gas and a disposable heated wire electrode into a welding torch. The welder moves the welding flame down the joint line as the welding progresses, and the electric arc at the contact point provides heat and filler metal for the weld. MIG/MAG welding is a fast and efficient method for joining metals and alloys. It is suitable for overhead or vertical welding due to its high heat input and fluidity. However, it is unsuitable for overhead or vertical welding due to the weld puddle's high heat input and fluidity.

Content Summary

- Metal Inert Gas (MIG) welding is widely used in the welding industry.

- MIG welding employs electricity to melt and combine metal components.

- Gas Metal Arc Welding (GMAW) is the parent technique of MIG welding.

- MIG welding is known by various names but has the same basic principles.

- MIG welding involves the parent metal, metal filler, weld metal, heat-affected zone, fusion line, and weld zone.

- MIG welding requires a special welding gun with various components.

- The contact tip in MIG welding helps reduce spatter.

- The electrode liner and conduit protect the electrode wire.

- The shielding gas is crucial for protecting the weld area.

- MIG welding uses wire electrodes for heat and filler metal.

- Polarity and voltage play a role in MIG welding.

- Metal can be transferred in MIG welding through short-circuiting, pulsed, spray, or globular mode.

- Short-circuiting mode is suitable for various orientations and pipe applications.

- Globular mode allows for high deposition rates and uses cheaper materials.

- Spray mode provides a steady stream of small molten metal droplets.

- Pulsed mode offers low spatter, excellent weld beads, and low heat-induced distortion.

- Shielding gases are essential for preventing atmospheric contact and ensuring arc stability.

- Different gases affect the welding process and properties of the weld.

- MIG welding is versatile and can be used on thick and thin sections.

- The welding process involves melting the surface of the base materials to form a weld pool.

- Shielding gas and a disposable heated wire electrode are used in MIG welding.

- The welder controls the welding flame and moves it along the joint line.

- MIG welding is efficient, fast, and suitable for various metals and alloys.

- Dissimilar metals can be joined using MIG welding.

- MIG welding produces minimal weld spatter.

- MIG welding is not ideal for overhead or vertical welding.

- MIG welding machinery is more complex than shielded metal-arc welding.

- MIG welding offers benefits like speed, efficiency, and versatility.

- MIG welding has some disadvantages, such as limited suitability for certain positions and more complex equipment.

- The content provides comprehensive information on MIG welding techniques and processes.

Frequently Asked Questions

MIG welding is considered one of the easier welding processes to learn, especially for beginners. The equipment is relatively straightforward to set up, and the process allows for good control and visual feedback. However, proper training and practice are necessary to achieve quality welds.

Common joint types in MIG welding include butt joints, lap joints, T-joints, and corner joints. These joints are prepared by cleaning and properly aligning the workpieces to ensure good penetration and fusion during welding.

MIG welding is versatile and can be used for thin and thick materials. However, for thicker sections, multiple passes or techniques like multi-pass or pulse welding may be required to achieve proper penetration and avoid excessive heat buildup.

Some challenges of MIG welding include the need for a clean welding surface, the possibility of weld spatter, and the sensitivity to changes in welding parameters. It may also be less suitable for welding materials with poor conductivity or applications requiring precise control over heat input.

To ensure safety during MIG welding, wearing appropriate PPE, including a welding helmet, gloves, and protective clothing, is crucial. Adequate ventilation or extraction should be provided in the welding area, and proper grounding of the workpiece and equipment is essential. Additionally, following safety guidelines and training in welding techniques and equipment usage is vital to minimise risks.