Stainless steel metal fabrication is widely used in industries where the final goods will be exposed to moist, humid, or corrosive environments. Its resistance to rust makes it a desirable material for use in products that will be used in corrosive conditions. However, stainless steel's resistance to corrosion is only one of its many benefits.

The eco-friendly material has many desirable properties, including long life, minimal upkeep, high tensile strength, malleability, and temperature resistance. It's aesthetically pleasing and practical in terms of cleanliness.

However, when working on a fabrication project, it is crucial to use the proper materials. There are a plethora of alternatives to choose from. Metals and their alloys provide various options for custom-fabricated products. Fabrication often makes use of carbon steel, aluminium, copper, brass, and stainless steel, among other materials. The material properties of the metal in question will be crucial in deciding which metal to use.

Why Is Stainless Steel So Popular In The Steel Industry?

Stainless steel's resistance to corrosion contributes to its widespread use in various contexts. Pitting corrosion, the localised breakdown of an oxide-covered metal in certain demanding settings, is the most common catastrophic cause of failure of metallic structures; nonetheless, they are still very good because of their general resilience. Custom metal fabricators in the steel industry favour stainless because of the material's low maintenance and high yield.

The adoption and major changes of structural stainless steel design regulations around the world in the past 15 years have spurred interest in the material due to its increasing use in the building industry. Due to its high initial material cost, stainless steel has traditionally been reserved for special and prestigious applications; however, thanks to design codes, increased awareness of the additional benefits of stainless steel, and a general trend towards sustainability, the material is finding more widespread use in conventional structures.

Although there are some similarities between these materials and regular carbon steel, there are also significant differences that must be taken into account when designing structures, including the nature of the stress-strain curve and the materials' response to cold work and elevated temperatures, which all have consequences at the ultimate, serviceability, and fire limit states.

What Are The Advantages Of Using Stainless Steel In Fabrication Projects?

The benefits of working with stainless steel far outweigh the disadvantages. However, the metal has drawbacks, such as a high initial cost, the need for high-quality equipment, and the likelihood of welding problems.

For projects involving the fabrication of metal, stainless steel may offer a variety of distinct advantages, depending on the sector in which you operate, including the following:

Corrosion Resistance

The resistance of stainless steel to rust is one of its main selling points. Stainless steel is a good material to market items that won't rust. Because of its resistance to corrosion, stainless steel is a good long-term investment.

Corrosion resistance in steel is maintained by chromium, and it can be altered by adjusting the alloy content. In general, lower-grade alloys perform better in wet environments. A higher alloy grade, however, is preferable when working with acids and alkalis.

Aesthetic Pleasure

It can be formed into virtually any form, making it ideal for use in architectural envelopes, interior design, and even outdoor furniture. As a unique and aesthetically pleasing material, it comes in a wide range of surface finishes, from matte to glossy, and even brushed, engraved, embossed, and tinted.

Stainless steel stands out among other metals in the building industry. Because of its excellent corrosion resistance and smooth surface it has quickly become a favourite among architects working in a wide range of modern architectural styles.

Due to its attractive appearance and its ability to display a distinct surface characteristic, technological advancement has quickly become a fan favourite.

Since the surface of stainless steel is so flawless, it can be painted any colour and still look great. It's also very handy for colouring, which is an additional perk. It takes a long time, and you can easily make any colour or pattern on the surface.

Maintenance Free

Working with stainless steel has long-term benefits that exceed the higher cost of materials that may deter the uninitiated. When making a choice, it is important to factor in the total cost of ownership over time. Concentrate on making a superior process and result by selecting a material that requires no upkeep, such as stainless steel.

100% Recyclability

Steel is one of the world's most recycled materials. Almost everything can be reused after being made from steel. A steel beam, for instance, can be reused to make other steel beams, a refrigerator, or a roof panel.

Since all parts of the steelmaking process are reusable, not a single fossil material or mineral is ever lost.

Steel's environmental friendliness is another attractive feature. The fact that it can be recycled provides this benefit because it effectively extends its lifespan indefinitely. Steel is a resource that will always be useful, so investing in it is worthwhile.

Steel scrap is a term for recycled steel. The two most common places to find steel scrap are:

- Post-consumer scrap

- Pre-consumer scrap

The steel used in the production process is known as pre-consumer scrap. This scrap steel is culled and put back into production without intermediate steps. In contrast, post-consumer scrap refers to steel that has already been used in a product and then recycled.

To transform scrap steel into a new product, it must first be collected, then shredded and shaped.

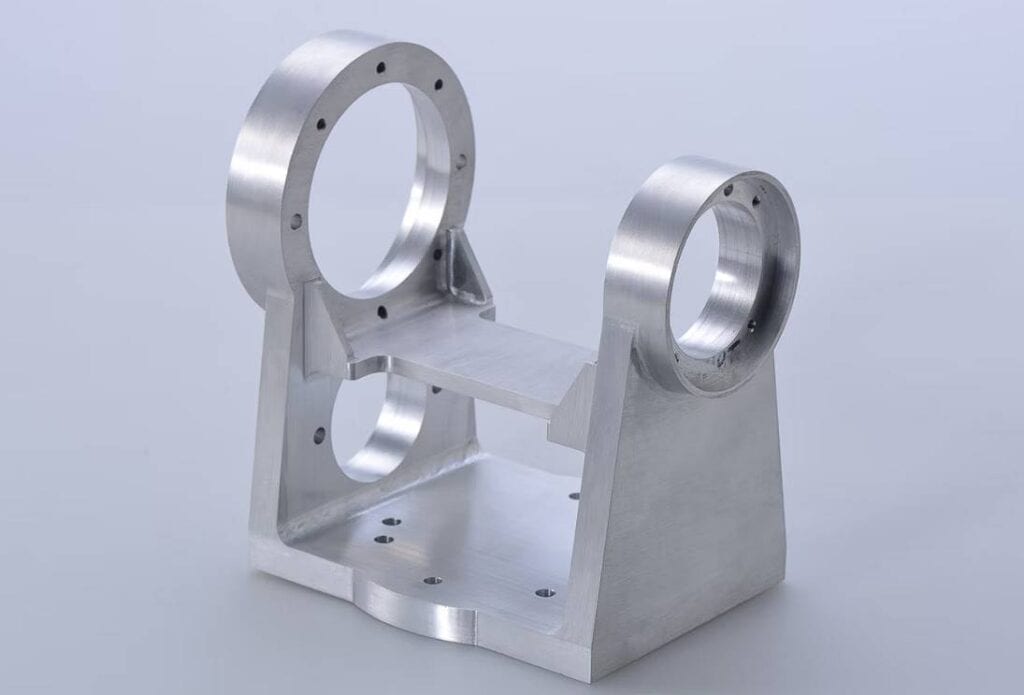

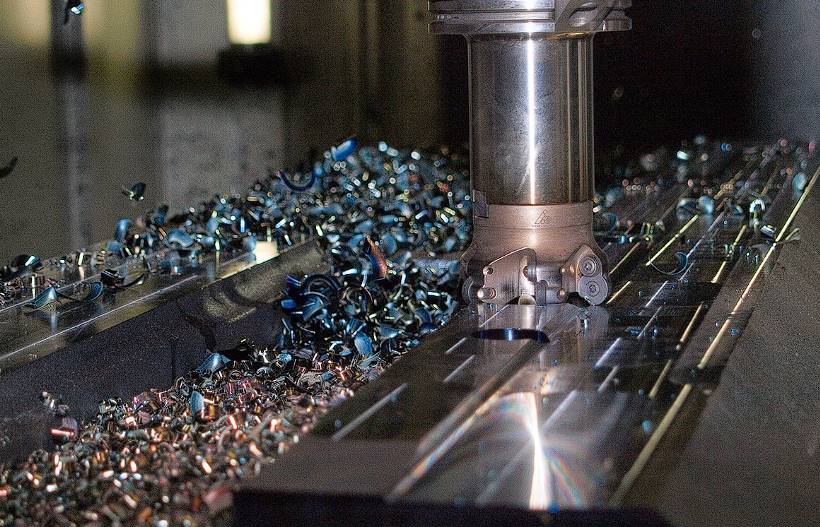

Simple To Fabricate

Stainless steel's workability is another quality that makes it a viable material for fabrication. Working with stainless steel is a breeze with practice and the right equipment. Stainless steel can be easily shaped, cut, bent, and welded.

Nickel is to thank for stainless steel's malleability, allowing us to produce unique parts quickly. While nickel isn't present in all stainless steels, it is in 75% of what we make. Stainless steel's austenitic structure is a result of the nickel content, which persists regardless of temperature.

Because of their austenitic structure, nickel-containing stainless steels are more malleable and formable and can be welded easily. For deep drawing, a higher nickel content is preferable.

Strength And Durability

Stainless steel is favoured for its many uses due to its strength and durability. Stainless steel's high tensile strength allows it to support weight without bending or breaking, safeguarding the durability of long-term structures. This quality is invaluable when building bridges, where the material must support heavy loads and withstand severe weather.

Stainless steel's durability also ensures consistent operation and longer service life for vital parts when used in the construction of machines and equipment. Stainless steel can be used as an architectural element because it is aesthetically pleasing and durable. Stainless steel's durability and resilience make it a go-to material for a wide range of industries.

Very Hygienic

Among metals, stainless steel is widely regarded as the cleanest option. As the best material that can be practically used to build sinks, benches, tables, and shelving, it has become the de facto standard for kitchens.

Unless you're willing to spend a fortune on material like titanium, stainless steel is the cleanest material you can use. Stainless steel's lack of pores makes it incredibly difficult for contaminants like dirt, bacteria, fungi, and viruses to take root and spread.

Its non-porous nature is strengthened by its corrosion resistance, extending the material's lifespan. Despite stainless steel's tough exterior, it can be easily shaped into any tool or appliance that may be required.

Sustainable

Half of all new stainless steel is created from recycled materials. Stainless steel can be recycled indefinitely. After its useful life is over, approximately 85% of stainless steel is recycled.

One of the many reasons stainless steel is so valuable is that it can be recycled into new metals. Only 29% of recycled stainless steel goes into making new carbon steel, while 56% goes into making new stainless steel.

When you choose stainless steel as your material, you can rest assured that the material's lifespan will far outweigh that of the product it is used in.

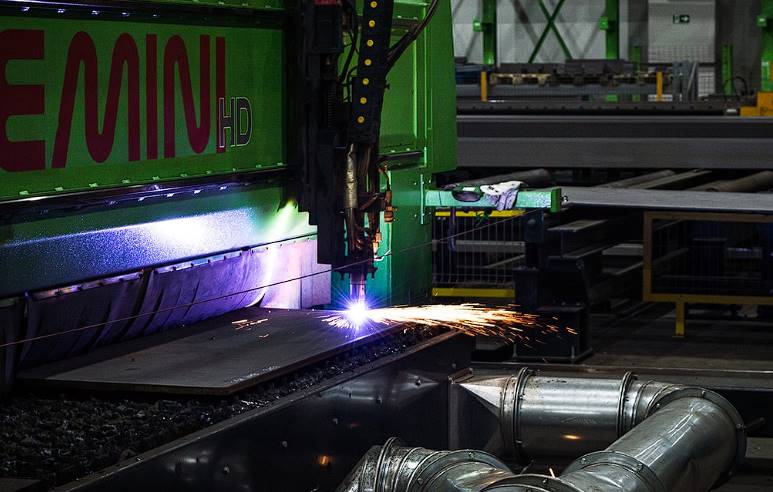

Resistance To Heat And Fire

Stainless steel's resistance to fire is an issue that has been debated for quite some time. Stainless steel has not been given an official fire rating, but several fire experiments have been conducted to compare its performance to that of other metals.

Stainless steel, aluminium, and galvanised steel are all tested side by side. Even after being subjected to extreme temperatures caused by fire, stainless steel still performed better than the other metals tested.

Stainless steel has the advantage that it will not contribute to the spread of flames in the event of a regular structural fire.

Stainless steel is widely used in the fabrication industry because it is resistant to oxidation even when heated to high temperatures. The percentage of chromium in the steel is directly proportional to its resistance. As a result, stainless steel is the most cost-effective and durable option for preventing and putting out fires in buildings.

Types Of Metal Fabrication Materials

The following is a list of the most common main types of metal used by companies that specialise in custom fabrication:

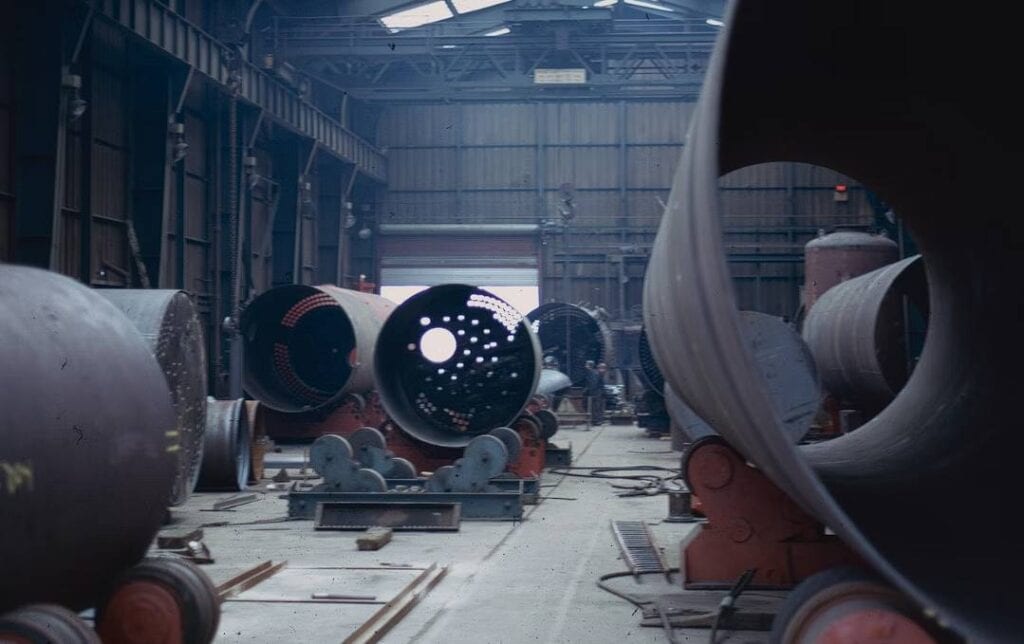

Stainless Steel Fabrication

Tanks, bins, and utensils in the food processing industry are typically made of stainless steel due to their high chromium content. Like carbon steel, stainless steel is easy to manipulate and provides fabrication versatility.

Stainless steel has a number of advantages over carbon steel, including resistance to corrosion, although it is typically much more expensive. The cost of stainless steel is significantly higher than that of other materials. Still, it's worth it in the long run for projects that benefit from its cleanliness, longevity, and resistance to corrosion.

Copper Fabrication

As copper is such a good heat conductor, it is often used to line the bases of stainless steel cookware. It has excellent corrosion resistance and is widely known for its electrical conductivity. Copper's malleability, durability, and ductility make it a useful material for piping and tubing, but it could be better for structural use. In the eyes of architects, it is aesthetically pleasing.

Copper is commonly used for exterior cladding, interior decoration, and roofing. Copper loses its shine and acquires a familiar green patina as it oxidises; this patina can be removed with regular cleaning. Copper's high material cost, which is higher than that of stainless steel, restricts its use to a subset of the construction industry.

Aluminium Fabrication

Similarly flexible is aluminium. Additionally, it is corrosion-resistant, pliable, lightweight, and strong. Cans, foils, electronics, appliances, kitchen utensils, and auto and aerospace components are just some of the many products and components that make use of aluminium.

Facades, roofing, cladding, window framing, rails, and doors are some of their structural and architectural uses. Unfortunately, aluminium is not as durable as steel under pressure. In addition, its malleability makes it more easily dented or scratched than stainless steel.

Carbon Steel Fabrication

Carbon steels range from low to high carbon content and are highly valued. They work wonderfully in constructing buildings like workplaces and bridges, producing automobiles, and creating tools, punches, blades, dies, high-strength wire, and springs. Carbon steels, in general, are more durable than stainless steel but are more susceptible to corrosion. They rust and corrode rapidly when exposed to moisture.

Brass Fabrication

Like stainless steel, brass is prized for its durability, shine, and resistance to corrosion and microbes. It is frequently used in a wide variety of decorative and structural contexts, from musical instruments to electronic packaging to roofing to facade cladding.

Brass has one major drawback, despite its widespread use in plating, polishing, and finishing products. Despite its corrosion resistance, it oxidises when exposed to air, resulting in a blackish tarnishing that is difficult to prevent and remove without extensive upkeep. Under the right conditions, brasses can also break from stress corrosion.

Conclusion

Stainless steel is a popular material in the steel industry due to its resistance to corrosion, long life, minimal upkeep, high tensile strength, malleability, and temperature resistance. It is also aesthetically pleasing and practical in terms of cleanliness. Stainless steel has several advantages, including corrosion resistance, aesthetic pleasure, maintenance-free options, 100% recycling, and easy fabrication.

Corrosion resistance is maintained by chromium, which can be adjusted by adjusting the alloy content. Lower-grade alloys perform better in wet environments, while higher alloy grades are preferred when working with acids and alkalis. Stainless steel's smooth surface allows for painting any color and is handy for coloring.

Stainless steel is maintenance-free, with no upkeep required, making it a cost-effective choice for various sectors. It is one of the world's most recycled materials, ensuring that no fossil material or mineral is lost. Steel scrap, which is a term for recycled steel, can be collected, shredded, and shaped.

Stainless steel's workability is another quality that makes it a viable material for fabrication. It can be easily shaped, cut, bent, and welded, thanks to its nickel content, which persists regardless of temperature. This austenitic structure allows for more malleable and formable parts, making it suitable for deep drawing.

Stainless steel's strength and durability make it a go-to material for various industries, including bridges, machine and equipment construction, and architectural elements. It is also considered the cleanest option, as it has a lack of pores, making it difficult for contaminants like dirt, bacteria, fungi, and viruses to take root and spread. Stainless steel is a durable and cost-effective material due to its non-porous nature, corrosion resistance, and versatility. It is a popular choice for various applications, including food processing, automotive, and aerospace. Stainless steel is a highly durable material that can be recycled indefinitely, with 85% of new steel being recycled after its useful life. Its resistance to heat and fire is debated, but it has been found to perform better than other metals tested.

There are several types of metal fabrication materials used by companies specializing in custom fabrication. Stainless steel is commonly used in tanks, bins, and utensils in the food processing industry due to its high chromium content. Copper, a heat conductor, is used for piping and tubing, but its high material cost restricts its use to a subset of the construction industry. Aluminium is also a versatile and corrosion-resistant material used in various products and components, including facades, roofing, cladding, window framing, rails, and doors.

Carbon steel, with varying carbon content, is highly valued for its durability in construction, automobiles, and tools. However, it is more susceptible to corrosion and rusts rapidly when exposed to moisture. Brass, like stainless steel, is prized for its durability, shine, and resistance to corrosion and microbes. However, it has a major drawback: it oxidizes when exposed to air, resulting in a blackish tarnishing that is difficult to prevent and remove without extensive upkeep.

Content Summary

- Stainless steel is widely used in industries exposed to moist, humid, or corrosive environments.

- It offers resistance to rust, making it desirable for products in corrosive conditions.

- Stainless steel has long life and requires minimal upkeep.

- It has high tensile strength, making it a strong material for fabrication.

- Stainless steel is malleable and can be easily shaped.

- It has temperature resistance and can withstand high and low temperatures.

- Stainless steel is aesthetically pleasing and can be used in architectural design.

- It is practical in terms of cleanliness and hygiene.

- The material properties of stainless steel make it a popular choice in metal fabrication.

- Stainless steel's corrosion resistance is one of its main advantages.

- It can be used in wet environments and is suitable for working with acids and alkalis.

- Stainless steel can be formed into various shapes and is ideal for architectural applications.

- It comes in different surface finishes, including matte, glossy, brushed, engraved, embossed, and tinted.

- Stainless steel is preferred by architects for its corrosion resistance and smooth surface.

- It requires minimal maintenance and is considered a long-term investment.

- Stainless steel is 100% recyclable and can be reused indefinitely.

- It is one of the most recycled materials in the world.

- Steel scrap can be collected, shredded, and shaped to create new products.

- Working with stainless steel is simple and requires the right equipment.

- Stainless steel can be easily shaped, cut, bent, and welded.

- Nickel content in stainless steel contributes to its malleability.

- Stainless steel has high strength and durability.

- It can support weight without bending or breaking.

- Stainless steel is suitable for building bridges and withstanding severe weather conditions.

- It ensures consistent operation and longer service life for vital parts in machines and equipment.

- Stainless steel is hygienic and clean, making it ideal for use in kitchens and food processing.

- Its non-porous nature prevents dirt, bacteria, fungi, and viruses from spreading.

- Stainless steel is sustainable and can be recycled into new metals.

- Approximately 85% of stainless steel is recycled after its useful life.

- It is cost-effective and has a longer lifespan compared to other materials.

- Stainless steel has resistance to heat and fire.

- It has been tested and performs well compared to other metals in fire experiments.

- Stainless steel does not contribute to the spread of flames in regular structural fires.

- Stainless steel fabrication is commonly used in the food processing industry for tanks, bins, and utensils.

- Copper is often used in stainless steel cookware due to its heat conductivity and corrosion resistance.

- Copper is aesthetically pleasing and commonly used for cladding, decoration, and roofing.

- Aluminium is corrosion-resistant, lightweight, and strong, making it suitable for various products and structural uses.

- Carbon steel is highly valued for constructing buildings, producing automobiles, and creating tools.

- Carbon steel is more durable than stainless steel but more susceptible to corrosion.

- Brass is known for its durability, shine, and resistance to corrosion and microbes.

- It is used in decorative and structural applications but requires upkeep to prevent tarnishing.

- Brass can break from stress corrosion under certain conditions.

- Stainless steel is preferred in metal fabrication due to its wide range of advantages.

- The material's resistance to corrosion is a significant factor in its popularity.

- Stainless steel is increasingly used in conventional structures due to design codes and sustainability trends.

- Stainless steel's strength and durability make it suitable for a wide range of industries.

- It offers a hygienic and clean solution for sinks, benches, tables, and shelving.

- Stainless steel contributes to environmental friendliness through its recyclability.

- It can withstand high temperatures, making it suitable for fire prevention in buildings.

- There are different types of metals used in fabrication, including stainless steel, copper, aluminium, carbon steel, and brass.

Frequently Asked Questions

Stainless steel may have a higher initial cost compared to some other metals. However, its long-term benefits, such as durability, corrosion resistance, and recyclability, make it a cost-effective choice in many applications. The minimal maintenance and replacement costs of stainless steel further contribute to its cost-effectiveness.

Stainless steel finds extensive use in metal fabrication across various industries. It is employed in constructing architectural structures, such as bridges and buildings. Stainless steel is also used in manufacturing equipment, machinery, automotive components, kitchen appliances, and artistic sculptures.

Stainless steel fabrication involves several processes, including cutting, welding, bending, forming, and finishing. Cutting methods may include shearing, sawing, or laser cutting. Welding techniques like TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) are commonly used.

Bending and forming are achieved through press brakes or rolling machines. Finally, finishing techniques like grinding, polishing, or coating may be applied to enhance the appearance and performance of the stainless steel components.

When selecting stainless steel for metal fabrication, important factors include:

- The specific application requirements.

- Desired corrosion resistance.

- Mechanical properties.

- Cost considerations.

- Any regulatory or industry standards that need to be met.

Consulting with experts in stainless steel fabrication can help in making informed decisions.

Stainless steel requires minimal maintenance compared to other materials. Its resistance to corrosion and staining reduces the need for frequent cleaning or protective coatings. However, periodic cleaning with mild detergents or stainless steel cleaners can help maintain its aesthetic appeal and remove surface contaminants.