Welding is one of those skills that we only give a little thought to once we need it. After that, we see the welding trade everywhere; it is essential to many aspects of modern life. When you first start looking into welding, there is a finite amount to discover.

In this blog, we'll explore welding, a fascinating and under-explored topic. Welding has come a long way since its early days and now plays an important role in many fields. Discover the undiscovered advantages of welding.

Interesting Facts That You May Not Know About Welding

Welding is one of the earliest technological processes still in use today. Even before the discovery of fire, it is likely that people were using heated rocks to forge implements and weapons. Although we have progressed greatly since then, welding still plays a vital role in our daily lives. Welding helps us feel secure in our surroundings and also allows us to make stunning works of art.

Here is a list of information about welding that you probably didn't know but think you'll find interesting and informative.

The History Of Welding Goes Back Thousands Of Years.

The history of welding goes back at least 10,000 years, making it one of the oldest technologies. It is difficult to prove that prehistoric humans were already melting rocks together in the absence of fire in order to forge implements and weapons.

However, by the Bronze Age, people had figured out how to smelt copper and tin into useful tools and weapons. They did this by melting rocks in an oven, adding metal ore, and heating everything together until it melted.

There's also proof that the Iron Age people in the region of what is now Turkey could heat rocks with some charcoal to make iron and steel. After melting the materials together, they'd use a mould to cast their desired object.

Welding Safely Necessitates The Use Of Specialised Equipment.

Personal protective equipment (PPE) is crucial for keeping welding jobs safe and secure. Protect your eyes and face from flying debris and sparks with a welding helmet, goggles, or a face shield. Hearing loss can occur from prolonged exposure to welding, so it's important to safeguard your ears. A welding respirator is a must to protect yourself from breathing in dangerous welding fumes.

Welding gloves, a welding jacket, and fire-resistant clothing like an apron are all great ways to keep yourself safe from sparks and other hazards. Complete your outfit with a pair of welding boots to keep your feet and legs safe from flying sparks, and make sure nothing explosive is in the area.

Because of the risks involved in welding, it's crucial that you're well-versed in the technique before attempting it. The experts at Welding Central advise that you equip yourself with the best safety gear possible and learn first aid fundamentals. Having a fire extinguisher handy is also crucial.

Modern Arc Welding Began In The Early 1800s.

Modern welding methods can be traced back to the work of Russian scientist Vasily Petrov in 1802 and Sir Humphry Davy in 1800. They were credited with discovering the continuous electrical arc, a crucial component in modern welding techniques.

Nikolai Benardos and Stanislaw Olszewski made significant progress in the late 19th and early 20th centuries. Carbon arc welding was the first practical technique developed between 1881 and 1882. This innovative method, which made use of metal electrodes, paved the way for future improvements in the welding industry and ultimately shaped the sophisticated practice into which welding has evolved.

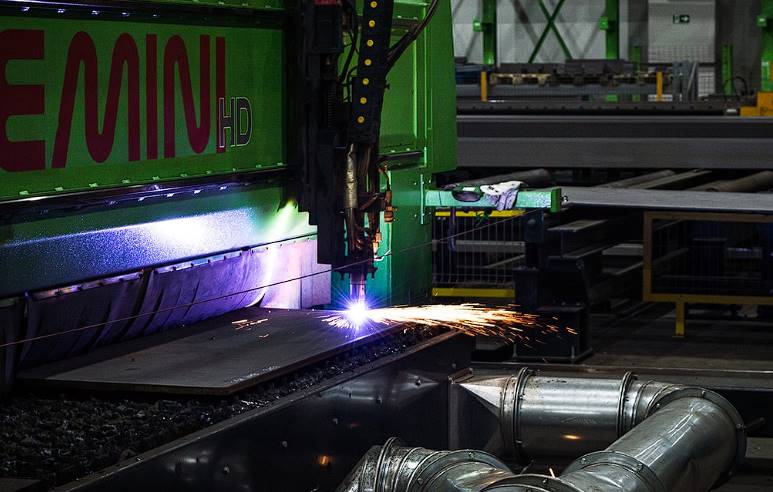

Welding Produces The Highest Temperature.

Gas welding, also known as oxyacetylene welding, is a type of welding that stands out from other types due to the exceptionally high temperatures it is capable of reaching. By combining fuel gases with oxygen, this method can produce temperatures of up to about 3,500 degrees Celsius. The high temperatures achieved through gas welding allow for metals' efficient and precise joining.

Welding produces heat at a temperature of about 3400 K. At the same time, the sun, the celestial powerhouse, emits heat at a temperature of about 5800 K. This side-by-side comparison demonstrates how gas welding's exceptional heat capabilities allow for the manipulation of metals and the creation of strong, seamless joints for a wide range of industrial uses.

Heat Is Not Required For All Types Of Welding.

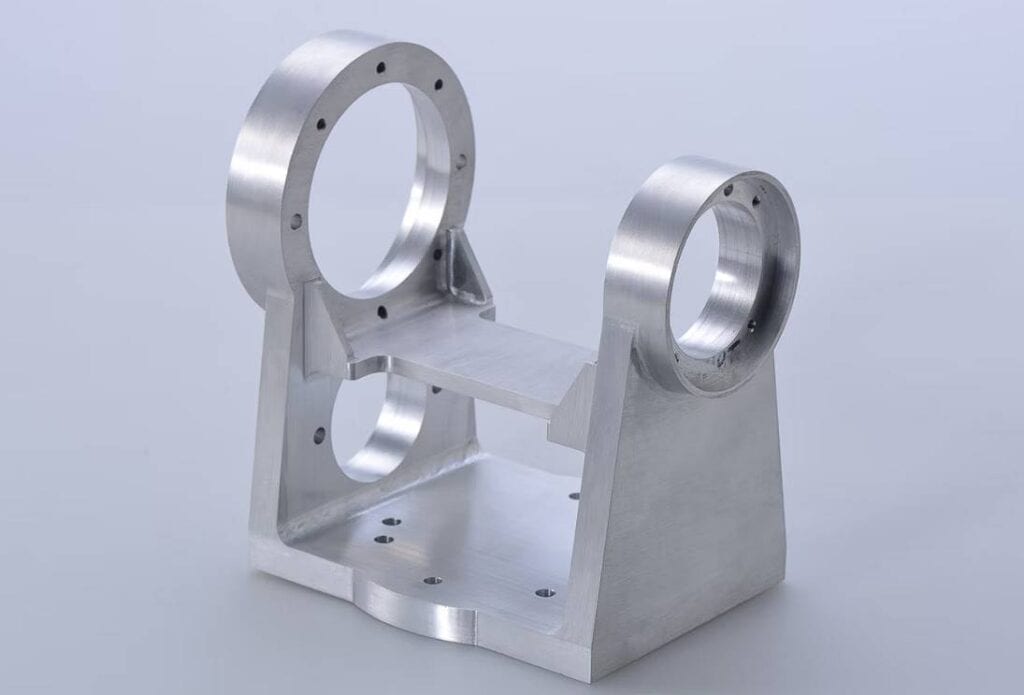

It's surprising to some people that there are welding techniques that don't require the use of heat. Arc-air welding is a common technique used in the fabrication of aluminium structures. Arc-air welding is an alternative method to conventional welding that relies on air pressure rather than an electric arc to join metals.

This novel method allows welders to safely and effectively work with aluminium, a metal notoriously vulnerable to overheating. Arc-air welding, which uses air pressure as its driving force, is an excellent option for the fabrication of aluminium structures that showcase high levels of craftsmanship and durability.

People Have Welded In Space

Strange as it may seem, welding can take place in outer space. Cold welding is the joining of metals through physical contact in space. This allows the two pieces to join without further melting being required. If this scares you, try not to worry too much; such things rarely occur in space.

Welding Technology Progressed During World Wars I And II

Many countries conducted welding research during World War I to determine the best methods for military machinery and equipment. This led to the first welded ships and aeroplanes and advances in bridge-building and other areas.

In the 1920s, shielding gas was developed, marking progress in welding technology. Welding technology advanced greatly during World War II, as it had during World War I, thanks to developments in automatic welding, alternating current, and welding fluxes. In 1941, the Gas Tungsten Arc Welding (GTAW) method was developed.

There Are Many Industries That Use Welding.

The ability to weld is extremely versatile and can be applied to a wide variety of different fields. The most common applications are:

- Manufacturing of structural and architectural metals

- manufacturing of motor vehicles

- Mining

- Agricultural manufacturing

When it comes to welding jobs, these others are just as important:

- Aerospace industry

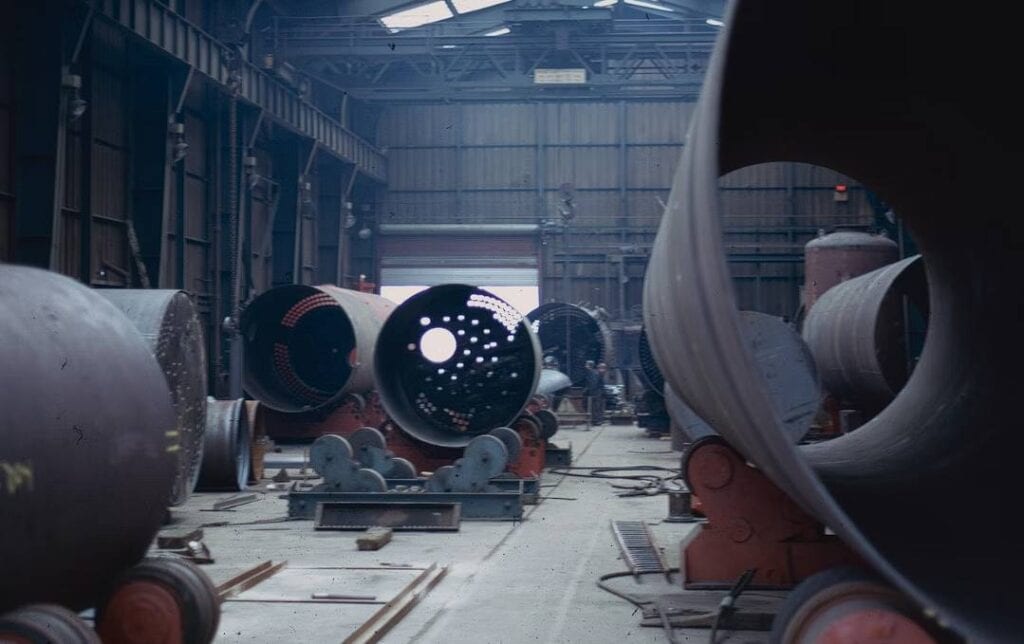

- Shipbuilding industry

Welding is required in more than half of all products made by humans. Welding is also necessary for the use of many vehicles, buildings, and other structures.

Welding Helped Us Invent Electricity

Welding has allowed us to do more than only construct things; it has also led us to an essential component of nature that we rely on regularly. Welding was developed because no one had yet figured out how to generate electricity with magnetism and electric current. After welding's popularity skyrocketed, researchers dove deep to uncover its energy secret.

Even Without A Certificate, You Can Become A Welder.

Unlike many other professions, welding does not necessitate formal education to enter the workforce. As a result, many people, even those without the most advanced degrees, consider it a viable career option. Apprenticeships and other forms of hands-on training give aspiring welders a foot in the door, opening up a wide range of career options.

Bronze Wasn't The First Metal Humans Used

It is estimated that bronze was discovered around the year 5,000 B.C. and that it was the first metal to be used extensively. All tools up until that point were hewn from stone or wood. The Palaeolithic Neanderthals of modern-day France did, however, have access to metals that they could have used to forge implements and weapons. Raw materials may have been contained in meteorites that crashed into their area during the Stone Age.

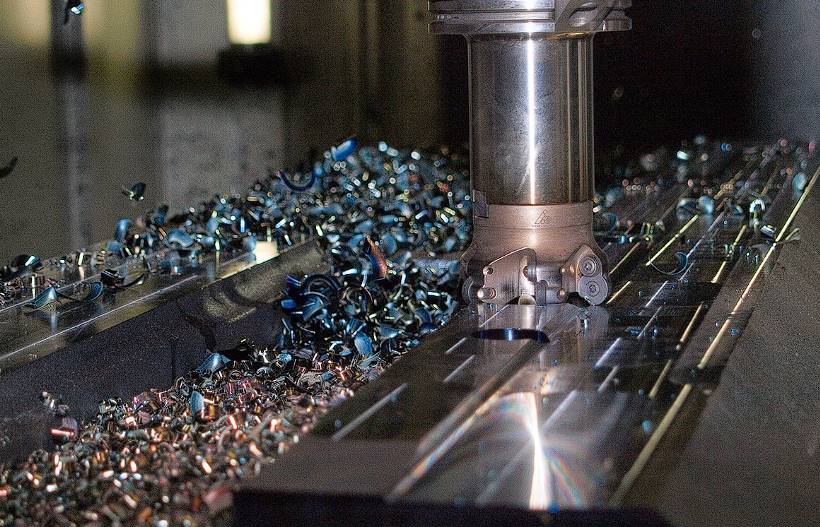

There Are Different Welding Techniques

There are numerous welding techniques, but some are not widely used because they require more advanced equipment than is currently available. It was only sometimes the case that people would use modern techniques like laser welding and electron beam welding to create highly complex tools and machines. Forge welding and oxy-fuel welding were among the earliest methods of welding, predating the development of more sophisticated techniques.

Welding Arcs produce Radiation.

Welding is no exception to the rule that anything that produces light and heat also produces radiation. Welding arcs produce UV radiation, which can cause skin damage and increase the risk of skin cancer in the same way that sunlight can; when it comes to avoiding sun damage, while welding, many people only cover areas where sparks or burns could hit.

The Importance Of Welding In Plastics

Welding demonstrates its adaptability by allowing for the joining of plastics in addition to metals. Welding is essential in the automotive and electronics industries for joining plastic components. Ultrasonic welding is a common technique that uses high-frequency sound waves to generate heat within the molecules of plastic.

When these molecules are heated, they fuse and form a strong, seamless joint. This cutting-edge method of welding is crucial in the assembly of a wide range of automobiles and electronic gadgets because it allows for the creation of complex plastic components and guarantees accurate fitting. Because of its versatility, welding is used in a wide variety of manufacturing applications.

Electricity Was Required For Welding To Be Useful.

Electricity was invented between 1831 and 1879, and then welding could be utilised to aid advanced manufacturing. Welding was practical once other electrical devices like motors and generators were developed.

In an ideal world, this would suggest that welding would only have a little utility prior to the development of electrical power. However, it's unlikely that electricity would have been generated without the preexisting, primitive welding techniques.

William W. Jacques developed a method of welding in 1885 called resistance welding, which relied primarily on electrical current to generate heat.

Underwater Welding Is Possible.

Hyperbaric welding is a technique that makes welding underwater possible, despite the fact that it seems physically impossible. Incredible as it may sound, this method makes welding possible in damp settings or in enclosed areas meant to maintain humidity.

When fixing ships, offshore platforms, or pipelines in harsh conditions, hyperbaric welding has proven its worth time and time again. Intricate repairs and maintenance can be performed by trained welders deep below the water's surface using this approach, which involves producing a controlled atmosphere favourable to welding. Hyperbaric welding has improved underwater maintenance drastically, protecting marine infrastructure for longer.

Welding Plays A Major Part In Everyday Life

Welding is a vital skill that has wide-ranging social and economic implications. Welding is used in the production of roughly 50% of all products, which is quite a feat! Welding plays a critical role in the production of many products we rely on every day, from cars and skyscrapers to complex computers.

Welding processes produce long-lasting and dependable products because of their ability to maintain structural integrity. The reliable structures, cutting-edge technologies, and hardworking machines that support our modern society would not exist without welding.

The Development Of New Types Of Weapons Was Helped By Welding.

New types of weapons were made possible by welding that could not have been made any other way. J. Robert Oppenheimer, credited with developing the first nuclear bomb in 1945, began his career as a welding scientist.

Welding was crucial in developing a wide variety of weapons, including those used in World War II and modern conflicts. Welding, for instance, was instrumental in discovering how to join metals with other materials like leather and plastic, without which we might not have been able to create firearms and knives.

Even In The Middle Ages, Welding Was Beneficial To People.

Welding has always been an important skill, but during the Middle Ages, it became increasingly popular for decorative purposes rather than practical ones like shipbuilding and toolmaking. Due to a lack of oxygen, mediaeval blacksmiths could not use torches to forge metal.

As a result, they shifted their focus to the creative side of welding by making elaborate metalwork for decoration and aesthetics. This shift paved the way for producing magnificent metal sculptures, creative embellishments, and elaborate designs gracing the architectural wonders of the era in question. During the Middle Ages, art and welding came together in a way that would forever change the face of craftsmanship and the arts.

There Is Wet Welding And Dry Welding.

Wet and dry welding are the two most common types of processes used in welding. Dry welding is done in an area not directly exposed to water, while wet welding takes place in an area surrounded by water. Despite the name, not all underwater welding is done in an underwater environment. The vast majority of welding jobs take place in dry conditions.

Wet welding is special because it can be done successfully in water, making it an indispensable method for maritime maintenance and building. However, dry welding is still widely used in many industrial settings because it consistently produces high-quality results.

Conclusion

Welding is one of the earliest technological processes, utilised to make tools and weapons as early as the Bronze Age. Safety gear including welding helmets, goggles, and face shields have come a long way since then. Gas welding, also known as oxyacetylene welding, may reach temperatures of up to 3,500 degrees Celsius, making welding the process that generates the highest temperature. This technology facilitates the fast and accurate combining of metals, producing robust, seamless junctions with a wide range of industrial applications.

As an alternative to traditional welding, arc-air welding uses air pressure to fuse metals rather than an electric arc, making it particularly well-suited to aluminium construction. To unite metals without additional melting, cold welding uses physical contact in empty space. During World War I, advancements in welding technology allowed for the creation of welded ships, aeroplanes, bridges, and other structures.

The aircraft and shipbuilding sectors, among others, rely heavily on welders. More than half of all human-made goods depend on it, and we can't live, work, or play without it. Welding also led to the discovery of electricity, a crucial part of the natural world.

Welding, unlike many other occupations, does not necessitate a college degree for entry, making it an attractive alternative for those who may not have the time or resources to pursue higher education. Aspiring welders can get their foot in the door through apprenticeships and on-the-job training. Using stone or wooden tools, the discovery of bronze in approximately 5,000 B.C. ushered in the era of widespread metalworking. Metals for forging tools and weapons were available to the Palaeolithic Neanderthals in present-day France. These metals may have originated from meteorites. Forge welding and oxy-fuel welding were among the early methods, but they did require specialised equipment.

Radiation from welding arcs can harm skin and increase the likelihood of developing skin cancer. In the automotive and electronics industries, welding is a must for attaching plastic parts. Using high-frequency sound waves to generate heat within plastic molecules, a widespread process known as ultrasonic welding can create strong, flawless seams. This cutting-edge technique is critical in automotive and electrical device assembly because it ensures proper fitment and adaptability.

Welding became feasible after the development of other electrical devices like motors and generators, which occurred between 1831 and 1879 thanks to the invention of electricity. With the help of electricity, William W. Jacques invented resistance welding in 1885. The ability to do hyperbaric welding underwater has allowed for greater underwater maintenance and protection of marine infrastructure. Approximately half of all manufactured goods include welding in some way. It has also contributed to the creation of cutting-edge weaponry, which saw service in both World War II and contemporary wars.

In the Middle Ages, welding was more commonly used for ornamental purposes than for functional ones like manufacturing ships and tools. Magnificent metal sculptures, embellishments, and designs in architectural marvels emerged as a result of this transformation. Wet welding is more prevalent than dry welding since it works in water, making it an essential technique for ship repair and construction.

Content Summary

- Welding is one of those skills that we only give a little thought to once we need it.

- After that, we see the welding trade everywhere; it is essential to many aspects of modern life.

- When you first start looking into welding, there is a finite amount to discover.

- Welding has come a long way since its early days and now plays an important role in many fields.

- Discover the undiscovered advantages of welding.

- Welding is one of the earliest technological processes still in use today.

- Even before the discovery of fire, it is likely that people were using heated rocks to forge implements and weapons.

- The history of welding goes back at least 10,000 years, making it one of the oldest technologies.

- Personal protective equipment (PPE) is crucial for keeping welding jobs safe and secure.

- Welding gloves, a welding jacket, and fire-resistant clothing like an apron are all great ways to keep yourself safe from sparks and other hazards.

- Complete your outfit with a pair of welding boots to keep your feet and legs safe from flying sparks, and make sure nothing explosive is in the area.

- Because of the risks involved in welding, it's crucial that you're well-versed in the technique before attempting it.

- The experts at Welding Central advise that you equip yourself with the best safety gear possible and learn first aid fundamentals.

- Having a fire extinguisher handy is also crucial.

- They were credited with discovering the continuous electrical arc, a crucial component in modern welding techniques.

- Carbon arc welding was the first practical technique developed between 1881 and 1882.

- Gas welding, also known as oxyacetylene welding, is a type of welding that stands out from other types due to the exceptionally high temperatures it is capable of reaching.

- The high temperatures achieved through gas welding allow for metals' efficient and precise joining.

- It's surprising to some people that there are welding techniques that don't require the use of heat.

- This novel method allows welders to safely and effectively work with aluminium, a metal notoriously vulnerable to overheating.

- Arc-air welding, which uses air pressure as its driving force, is an excellent option for the fabrication of aluminium structures that showcase high levels of craftsmanship and durability.

- Strange as it may seem, welding can take place in outer space.

- In the 1920s, shielding gas was developed, marking progress in welding technology.

- Welding technology advanced greatly during World War II, as it had during World War I, thanks to developments in automatic welding, alternating current, and welding fluxes.

- The ability to weld is extremely versatile and can be applied to a wide variety of different fields.

- Welding is also necessary for the use of many vehicles, buildings, and other structures.

- It is estimated that bronze was discovered around the year 5,000 B.C. and that it was the first metal to be used extensively.

- The Palaeolithic Neanderthals of modern-day France did, however, have access to metals that they could have used to forge implements and weapons.

- There are numerous welding techniques, but some are not widely used because they require more advanced equipment than is currently available.

- Forge welding and oxy-fuel welding were among the earliest methods of welding, predating the development of more sophisticated techniques.

- Welding is no exception to the rule that anything that produces light and heat also produces radiation.

- Welding is essential in the automotive and electronics industries for joining plastic components.

- This cutting-edge method of welding is crucial in the assembly of a wide range of automobiles and electronic gadgets because it allows for the creation of complex plastic components and guarantees accurate fitting.

- Because of its versatility, welding is used in a wide variety of manufacturing applications.

- William W. Jacques developed a method of welding in 1885 called resistance welding, which relied primarily on electrical current to generate heat.

- Hyperbaric welding is a technique that makes welding underwater possible, despite the fact that it seems physically impossible.

- Incredible as it may sound, this method makes welding possible in damp settings or in enclosed areas meant to maintain humidity.

- When fixing ships, offshore platforms, or pipelines in harsh conditions, hyperbaric welding has proven its worth time and time again.

- Intricate repairs and maintenance can be performed by trained welders deep below the water's surface using this approach, which involves producing a controlled atmosphere favourable to welding.

- Hyperbaric welding has improved underwater maintenance drastically, protecting marine infrastructure for longer.

- Welding is a vital skill that has wide-ranging social and economic implications.

- Welding is used in the production of roughly 50% of all products, which is quite a feat!

- Welding plays a critical role in the production of many products we rely on every day, from cars and skyscrapers to complex computers.

- New types of weapons were made possible by welding that could not have been made any other way.

- Robert Oppenheimer, credited with developing the first nuclear bomb in 1945, began his career as a welding scientist.

- Welding was crucial in developing a wide variety of weapons, including those used in World War II and modern conflicts.

- Welding, for instance, was instrumental in discovering how to join metals with other materials like leather and plastic, without which we might not have been able to create firearms and knives.

- Welding has always been an important skill, but during the Middle Ages, it became increasingly popular for decorative purposes rather than practical ones like shipbuilding and toolmaking.

- As a result, they shifted their focus to the creative side of welding by making elaborate metalwork for decoration and aesthetics.

- This shift paved the way for producing magnificent metal sculptures, creative embellishments, and elaborate designs gracing the architectural wonders of the era in question.

- During the Middle Ages, art and welding came together in a way that would forever change the face of craftsmanship and the arts.

- Wet and dry welding are the two most common types of processes used in welding.

- Dry welding is done in an area not directly exposed to water, while wet welding takes place in an area surrounded by water.

- Despite the name, not all underwater welding is done in an underwater environment.

- The vast majority of welding jobs take place in dry conditions.

- However, dry welding is still widely used in many industrial settings because it consistently produces high-quality results.

Frequently Asked Questions

Although welding is often linked to metals, its application extends to other materials, such as plastics, ceramics, and specific types of glass. This adaptability showcases the versatility of welding, making it a valuable technique in diverse industrial sectors beyond traditional metalworking.

Underwater welding presents distinctive challenges owing to the underwater environment's complexities and the essential requirement for specialised equipment and rigorous training. Welders must contend with water pressure, limited visibility, and potential hazards, making it a demanding yet crucial skill for marine construction and repair work.

Robotic welding undoubtedly provides efficiency and precision in industrial settings. However, human welders remain indispensable, especially when handling intricate and complex welding tasks that require meticulous attention and adaptability. Robotic automation and skilled human craftsmanship ensure optimal results and versatility in welding applications.

Welding, like any industrial process, can pose hazards if safety protocols are not diligently followed. Welders must prioritise safety by wearing suitable protective gear, such as helmets, gloves, and eye protection, and strictly adhering to safety guidelines. By doing so, they minimise risks and ensure a secure working environment.

Indeed, eco-friendly welding methods have emerged, aiming to mitigate the environmental impact of welding operations. These techniques focus on reducing emissions and energy consumption, promoting sustainability and environmental responsibility within the welding industry. By adopting eco-conscious practices, welders can contribute to a greener and more sustainable future.