It's easy to feel overwhelmed by the prospect of researching and contacting several different custom metal fabrication companies to get started on your new fabrication project.

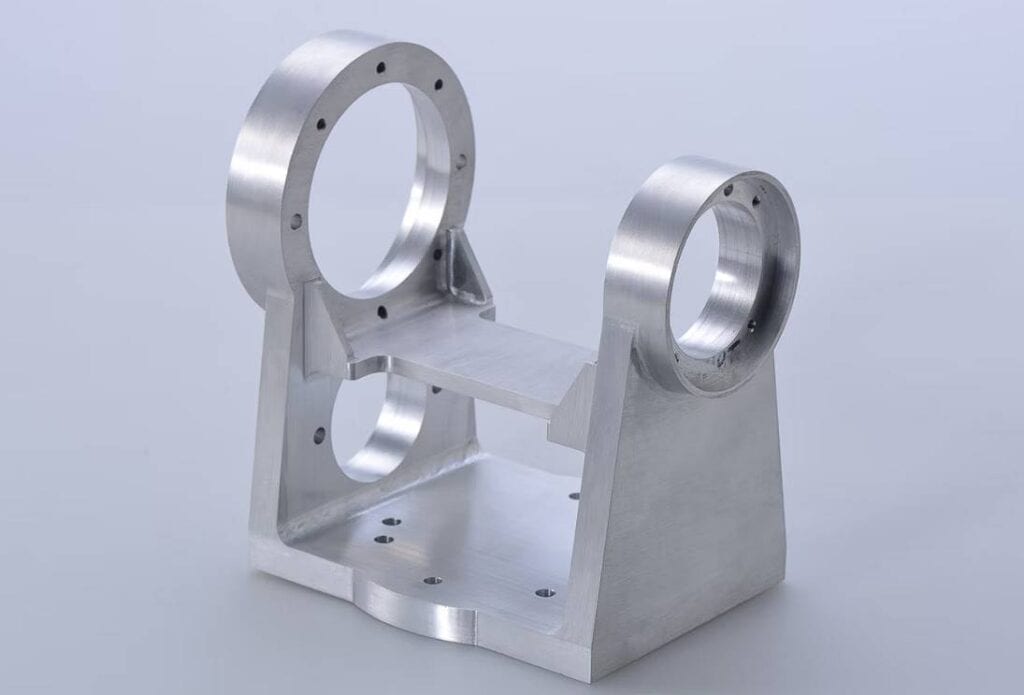

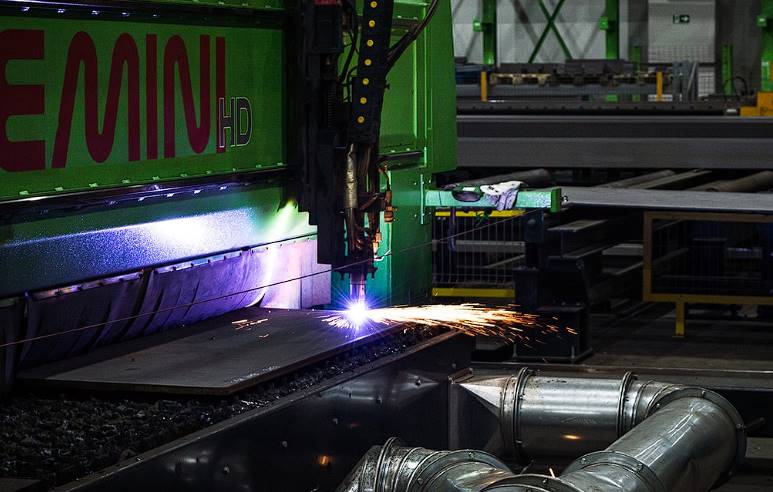

Metal fabrication is a broad term that covers a wide range of techniques used to transform raw metal into a finished product, including cutting, welding, milling, and casting. A company that offers comprehensive bespoke metal fabrication services is more than just a corporation; it's an integrated set of technologies used at various points in production to create the final product.

Misconceptions and assumptions about what a bespoke metal fabrication company can and cannot do might derail a person's research efforts when hiring a fabrication firm. The goal should be to know what to anticipate from a fabrication company.

Common Misconceptions About Metal Fabrication

Finding a reliable fabrication company to work with on your next project can be challenging. You need quality service at a fair price, but it sometimes needs to be clarified which service provider best suits your needs. Consider these misconceptions about metal fabrication before making a final choice.

The following are some common misconceptions you should be aware of before beginning your research and selecting a company to work with on your project.

Metal Fabrication Businesses Are All Essentially The Same.

A metal fabrication company can offer various services or none at all. Services vary greatly from one establishment to the next. The needs of your project will determine which option is best for you. Finding a fabrication company that can provide the services you need to finish your project to your fulfilment is important.

First, you should examine the competence of a metal fabrication firm. To begin, ensure that the shop you choose can fabricate your desired part geometry using the appropriate materials.

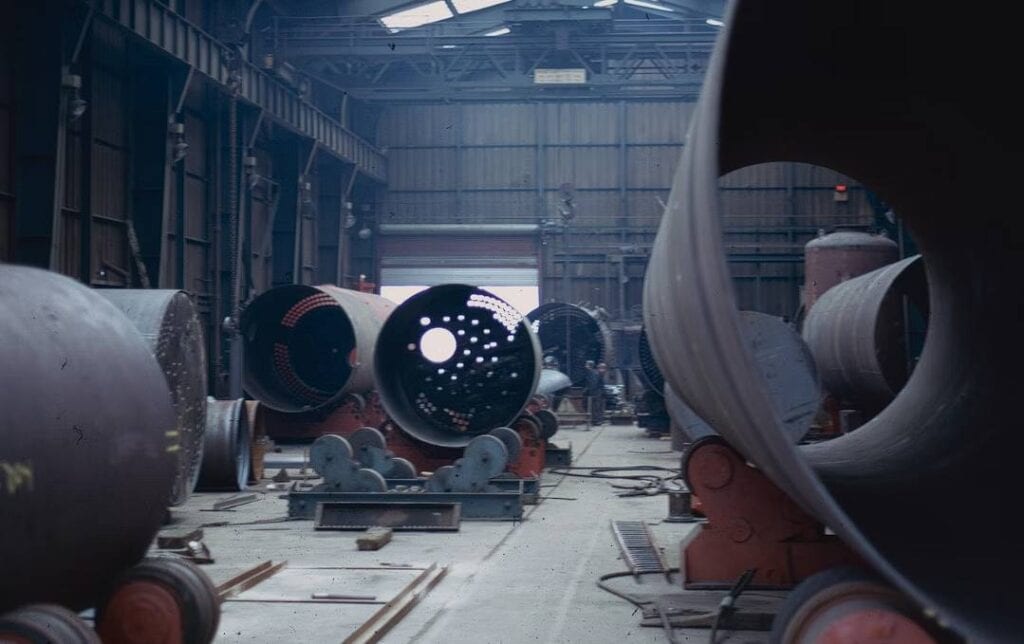

You should also check that the fabrication shop has enough room for your project and that the company serves your industry. The facility's square footage must be adequate to house your workers and their equipment without hampering output. Find a metal fabrication shop that offers everything you need for your project.

Fabricators Conduct Their Own Verifications

Understanding how to work within the complex legal framework is crucial for any industrial project. Some fabricators may insist they don't need outside help with the steps of compliance verification necessary to ensure these regulations are followed.

When accuracy and thoroughness are of the utmost importance, however, it is acceptable to use a professional compliance verification service. Fabrication businesses that have nothing to hide will have no problem partnering with these suppliers. Doing so shows they care about maintaining high standards in their field and complying with laws. Having third-party experts on board provides additional assurance, lessens the likelihood of mistakes, and lets everyone rest easy as the project moves forward. When everything must go perfectly, it's smart to put an emphasis on openness and responsibility by teaming up with reliable compliance verification providers.

Metal Fabrication Is Environmentally Hazardous.

There is a common misunderstanding that metal fabrication is inherently harmful to ecosystems. While it is true that waste is produced and energy is used, great strides have been made in the industry to promote sustainability. Metal fabricators are increasingly turning to recycled materials, which helps to cut down on extraction efforts. In addition, technological advancements have allowed for more eco-friendly production methods that use less energy.

Adopting these environmentally conscious practices brings metal fabrication in line with sustainability principles by placing an emphasis on the efficient use of resources and reducing waste. It is critical to recognise that metal fabrication and environmental protection can coexist peacefully as long as continuous advancements and conscientious decisions are made.

You Do Not Require An Engineer.

The first step in most metal fabrication projects is to create a design. This leads many to conclude that engineers need to be more correct. Incorrect; an engineer's duties lie more in manufacturing, such as checking the design's quality and creating prototypes. If you have an engineer look over your design, you may avoid making cheap assumptions that cost you big.

When design and engineering work together, the results of a fabrication project are at their best. Whether or not you have a working design, having an engineer on board is recommended.

A well-coordinated effort between designers and engineers is the cornerstone of any prosperous bespoke metal fabrication venture. Make sure all the necessary elements are in place before sending your design to fabrication so that it can be turned into working metal parts. Then we can start visualising our ideal world.

For instance, before moving on to the next step, the "design" phase for custom steel products must give way to the "fabrication design." The next step is engineering, prototyping, and finally, fabrication, after which the product is ready for sale. So, a lot goes on behind the scenes between the phases of design and production.

Full-service fabricators have industry leaders on staff who are happy to consult with engineers about metal fabrication processes, even if they are already involved in the design process.

The Best Price Guarantees A Greater ROI On A Project.

Finding the best value for your money by comparing prices and quality is sound advice. Preparing a budget is essential to the success of any new fabrication project researched. The project's financial success depends on finding the best possible price, so shopping around is important. It's important to remember that the fabricator with the lowest price is only sometimes the one who offers the best return on investment.

To compete for your custom, fabricators often fall into one of two broad categories in terms of their business approaches. Fabricators can compete with one another in a number of ways, with price being just one of them. There is a difference when comparing price to quality. You'll benefit from striking a balance, but investing in value will give your project a higher return on investment.

Good Presentation Means Good Fabricator.

The ability to deliver on promises made during a presentation is no guarantee of future success.

Don't get us wrong: we appreciate it when businesses effectively communicate and demonstrate their capabilities through well-crafted presentations. However, you should only make a final call based on that information with others. Anyone can make an impressive PowerPoint presentation, but this has little to do with a person's ability to produce high-quality work.

It's fine to pay attention to their presentation and hear them out, but you should also be wary of any slick rhetoric or empty promises they might make.

Metal Applications Are Interchangeable

There are a wide variety of metals to pick when planning a metal fabrication project, and some share comparable properties; however, this does not necessarily make them suitable for use in the same application. Metals can differ in their chemical makeup. Each metal has special qualities that make it useful in various contexts and yield different products.

For example, steel can be used in place of aluminium in most fabrication projects, but the opposite is not true. In comparison to steel, aluminium is lighter, more malleable, and easier to work with. It finds extensive use in the transportation industry and in a wide range of packaging applications. It's more costly and less durable than steel, though. Fabrication projects would benefit greatly from using steel instead of aluminium due to the former material's superior durability and resilience.

A Professional Appearance Ensures Good Results.

While it would be helpful if outward appearances were always indicative of inner truth, this is only sometimes the case. A metal fabrication shop's ability to deliver on promises is not ensured by how well they present their pitch. Feedback from other companies that have worked with the shops you are considering will give you a better idea of their history and abilities.

You can learn a lot about the shop's effectiveness, dependability, and customers' level of satisfaction by talking to them and reading their reviews. By doing your homework, you can avoid making a hasty decision based on incomplete information and increase your odds of success.

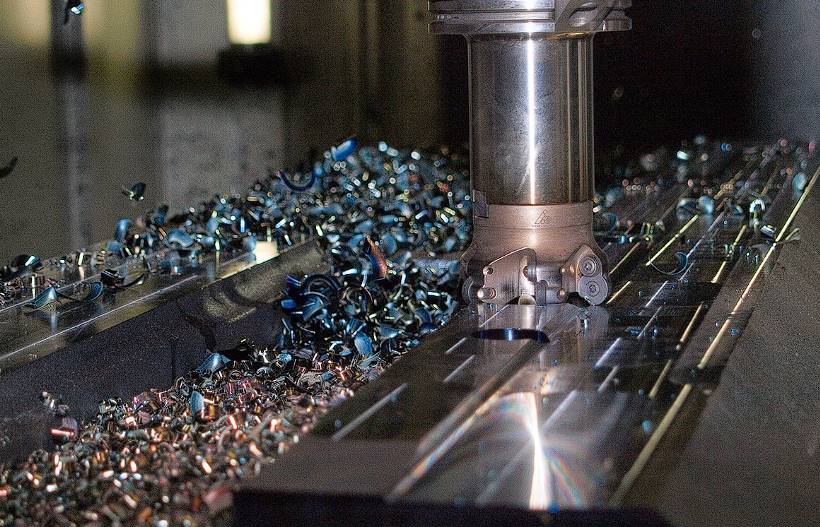

Metal Fabrication Is Easy

The idea that working with metal is simple is widely held but is far from the truth. Despite the greater automation made possible by technological progress, metal manufacturing still calls for high experience, precision, and competence. Fabricators of metals need a wide range of skills, including the ability to read complex blueprints, manage large pieces of equipment, and work with a variety of metals.

The fabrication process is complex and multi-step, requiring careful attention to detail at each stage, such as cutting and welding. Metal fabrication calls for a high level of technical skill, extensive experience, and expert handiwork to get the best results.

Product Inspections Are Not Necessary.

Having a professional fabricator on board is no assurance of a high-quality finished product. While most reputable metal fabricators have quality control specialists on staff, it's still a good sign if they welcome outside quality assurance checks. Inspections are essential to guarantee you get the high-quality goods you've paid for.

Professional status does not absolve a fabricator from the responsibility of rigorous quality control. Fabricators show their dedication to quality by giving customers peace of mind by letting third-party inspectors evaluate their work.

Multiple Vendors Are Required For Custom Metal Fabrication.

You don't need to source design, engineering, and assembly from three companies because your project has unusual requirements.

To finish a new project, a full-service fabrication company will almost never require the assistance of one or more outside vendors, despite the fact that it is not impossible for some shops to involve a third-party vendor in creating a new project. In-house design, fabrication, engineering, and assembly are performed from start to finish on every project, regardless of how one-of-a-kind the undertaking may be.

Stainless steel, aluminium, carbon steel, copper, and brass are just some of the metals that a full-service metal fabrication company can fabricate, so it's important to look for a company that can handle all of these metals in-house with the help of cutting-edge machinery and experienced workers.

Metal Galvanising Is Prohibitively Expensive.

Galvanising metal, or coating it with a protective layer, greatly increases its longevity and lowers the frequency of necessary repairs. Galvanisation is a crucial process that metalworkers may encounter. Hot-dip galvanising and other technological advancements have dispelled the outdated belief that galvanising costs too much.

We can see why people keep believing this falsehood. Galvanisation was once seen as a costly extravagance available only to the wealthy. The cost of galvanising used to be prohibitive for many people and businesses, but modern innovations and refinements have brought the process down to a more reasonable level. Galvanisation's advantages are so affordable now that practically anyone can use them. Due to its low cost and wide availability, galvanisation is now a standard method for preserving and protecting metals.

The Metal Fabrication Industry Is Dying

Despite what many may think, metal fabrication is far from a dying industry. Metal fabrication, on the other hand, is vital to many thriving industries, including the automotive, aerospace, and construction industries. The rising demand for customised metal products means the industry is still alive.

Increases in precision, efficiency, and adaptability in metal fabrication brought about by technological progress will ensure the field's continued importance in the industry. New approaches and developments promise to keep metal fabrication at the forefront of its field and ensure its continued importance to a wide range of businesses.

Conclusion

Using processes including cutting, welding, milling, and casting, metal fabrication is the intricate process of changing raw metal into a finished product. A trustworthy fabrication firm should provide a variety of options to accommodate your project. You need to evaluate the company's skill level, make sure they can manufacture your required part geometry using the right materials, and check that the facility has enough room for your project.

To ensure continued excellence and legal compliance, fabricators must undertake their own verifications. Using expert compliance verification services may guarantee precision and thoroughness, lessening the possibility of errors and making for a more successful project overall.

The use of recycled resources and environmentally friendly production methods means that metal fabrication is not intrinsically destructive to ecosystems. However, it is crucial to recognise that, with consistent improvements and responsible judgements, metal manufacture and environmental protection may coexist harmoniously.

Most metal fabrication projects do not necessitate the services of an engineer, whose responsibilities lie elsewhere in the production process, such as checking the quality of the design or developing a prototype. Custom metal fabrication projects rely heavily on designers' and engineers' ability to work together effectively.

Finding the lowest price ensures a higher return on investment (ROI). The highest return on investment isn't always the lowest price, thus it's important to create a budget before beginning any fabrication project.

Good presentations are no guarantee of future success, and you should be careful of boastful claims. Metal fabrication projects can use a broad variety of metals, and metal applications are generally interchangeable. Fabricating metal is a multi-stage process that calls for a high level of expertise, precision, and experience. Pick a place that has the equipment and expertise to work with any metal you throw at it, from aluminium and stainless steel to carbon steel and brass. Aluminium is more preferable to steel for most fabrication jobs since it is less expensive, more versatile, and easier to deal with than steel.

It's more expensive and doesn't hold up as well as steel, though. Feedback from prior customers is a good indicator of a shop's efficiency, dependability, and customer happiness, rather than the shop's professional appearance.

Inspections of finished goods are unnecessary, but a fabricator's expertise does not absolve them of the need of strict quality control. Fabricators that are serious about quality will welcome outside inspections of their products. Rather than outsourcing any of the design, manufacturing, engineering, or assembly processes, a full-service metal fabrication firm handles everything in-house. Because of its low cost and widespread availability, galvanisation has become a de facto standard in the metalworking industry.

Metal fabrication is essential to many thriving industries, such as automotive, aerospace, and construction, despite the rising need for individualised metal goods. The industry will remain relevant because of technological advancements and novel techniques, and it will remain at the cutting edge of its area because of these same factors.

Content Summary

- Metal fabrication encompasses various techniques like cutting, welding, milling, and casting.

- A comprehensive bespoke metal fabrication service integrates multiple technologies for the final product.

- Misconceptions about fabrication companies can hinder research efforts for hiring the right firm.

- Different metal fabrication companies offer varying services to suit project needs.

- Competence and expertise in fabricating specific part geometries are essential considerations.

- Compliance verification can be outsourced to ensure adherence to complex legal regulations.

- Metal fabrication has become more environmentally sustainable with advancements in recycling and energy efficiency.

- Engineers play a crucial role in the manufacturing and quality control aspects of fabrication projects.

- Collaboration between designers and engineers is crucial for successful metal fabrication.

- The best price doesn't always guarantee the highest return on investment in fabrication projects.

- A professional presentation doesn't always reflect a fabricator's ability to deliver on promises.

- Different metals have unique properties and are not always interchangeable for specific applications.

- Evaluating a fabricator's history and customer feedback is vital for making the right decision.

- Metal fabrication is a complex process that requires technical skills and precision.

- Product inspections are essential to ensure high-quality finished goods.

- Full-service fabrication companies can handle all aspects of a project without involving multiple vendors.

- Galvanising metal is no longer prohibitively expensive due to technological advancements.

- Metal fabrication is a thriving industry, essential for various sectors like automotive and aerospace.

- Technological progress ensures metal fabrication's continued importance and adaptability.

- Sustainable practices in metal fabrication reduce their impact on the environment.

- The wide range of metal options available for fabrication projects must be carefully considered.

- Compliance with legal regulations is essential for fabricators to maintain high standards.

- The fabrication process involves several steps, including design, engineering, and assembly.

- Fabrication companies may collaborate with engineers to optimise project outcomes.

- Quality control is critical for ensuring the delivery of high-quality fabricated products.

- A well-equipped and experienced fabrication shop can handle unique and challenging projects.

- Using recycled materials in metal fabrication promotes sustainability and reduces waste.

- Custom metal fabrication services can vary significantly from one company to another.

- Metal fabrication is an integral part of industries like construction and manufacturing.

- Collaboration between fabricators and compliance verification providers enhances project reliability.

- Metal fabrication requires expertise in handling a wide range of metals and materials.

- The fabrication industry continually evolves with technological advancements.

- Engineers play a vital role in ensuring the quality and functionality of fabricated products.

- A careful balance between price and quality is crucial for a successful project.

- Metal fabrication companies should have adequate space and resources to handle projects effectively.

- Galvanisation improves metal durability and reduces maintenance requirements.

- Third-party inspections add an extra layer of assurance to fabricators' work.

- Metal fabrication is a complex and multi-step process that demands attention to detail.

- The importance of finding a fabrication company that suits project needs cannot be overstated.

- Environmental concerns in metal fabrication have led to greener and more sustainable practices.

- Metal fabrication contributes significantly to various industries' growth and development.

- The misconception that fabrication companies are all the same can lead to poor choices.

- Finding the right fabrication company can be challenging but is crucial for project success.

- Advanced technology has made metal fabrication more efficient and cost-effective.

- Professional compliance verification ensures adherence to industry standards and regulations.

- Metal fabrication companies need to demonstrate their ability to meet project requirements.

- The fabrication process requires skilled technicians and advanced equipment.

- Quality control measures and third-party inspections ensure the fabrication of high-quality products.

- Collaboration between designers, engineers, and fabricators is vital for successful projects.

- A well-researched approach to selecting a fabrication company leads to successful project outcomes.

Frequently Asked Questions

Absolutely! Metal fabrication suits projects of all sizes, including small-scale and custom projects. Skilled fabricators can adapt their processes to meet the unique requirements of each project, regardless of its scale.

Not at all. While metal fabrication is crucial in industrial sectors, it is also widely utilised in various fields. From architectural and artistic applications to automotive and aerospace industries, metal fabrication finds applications in diverse sectors.

Yes, it can. With advanced machinery and CAD software, fabricators can precisely create intricate and complex designs. Metal fabrication can bring your design ideas to reality, whether it's complex geometries, customised patterns, or detailed engravings.

The duration of a metal fabrication project can vary depending on factors such as project complexity, size, and fabrication techniques. By working closely with your chosen fabricator, you can establish realistic timelines and ensure efficient project completion.

Skilled welders employ proper techniques and follow industry standards to create strong and reliable welds. When performed correctly, welding enhances the structural integrity of metal components, ensuring their durability and performance.