Flat sheets are transformed into precisely and beautifully folded products, ready for distribution or sale, by folding machines, which are unsung heroes in the complex world of metal processing. The adaptability and efficiency of folding machines play a vital part in the production process, providing high-quality finishes that satisfy the standards of various industries.

The fact remains, however, that not all folding machines are made equal. Various folding requirements, material kinds, and production volumes are considered when designing each type, which results in developing specialised functionality. Throughout our exploration of the intriguing world of folding machines, this blog aims to dissect the complexity of these indispensable devices and highlight the variety of their applications.

You are welcome to join us as we investigate the various kinds of folding machines, regardless of whether you are an experienced professional in the printing sector, the proprietor of a company that wants to streamline the creation of marketing materials, or simply curious about the process by which paper is transformed into artistic folds. Each machine has a distinct function, improving the efficiency, precision, and inventiveness of paper processing. From the straightforwardness of manual folders to the complexity of automated systems, we will investigate how each machine type serves a unique purpose.

Manual Folding Machines

While basic in operation, these machines are instrumental in transforming sheets of paper into neatly folded documents, enhancing productivity and precision in tasks that require a personal touch.

Manual Folding Machines:

Manual folding machines are the most straightforward type of folding equipment available. They require the operator to feed and fold the paper physically, offering a hands-on approach to paper folding. This type of machine is particularly suitable for operations that deal with a limited volume of paper or where the intricacies of specific folds are paramount.

Features And Benefits:

- Portability: Their compact size makes manual folding machines easy to transport and set up in various environments, from small offices to educational institutions.

- Energy Efficiency: These machines are highly energy-efficient and operate without electricity. This reduces operational costs and supports eco-friendly practices.

- Versatility: Despite their simplicity, manual-folding machines can handle a variety of folds, from basic half-folds to more complex brochure and accordion folds. This versatility makes them suitable for various applications, including producing marketing materials, educational pamphlets, and administrative documents.

Ideal Use Cases:

Manual folding machines excel in scenarios where the volume of documents is manageable and the precision of hand-folded documents is desired. They are instrumental for:

- Small businesses looking to create professional-looking brochures and pamphlets without significantly investing in automated machinery.

- Educational institutions require the production of informational booklets and flyers for events and announcements.

- Home offices where occasional document folding is needed, ensuring that presentations and mailouts are neatly prepared.

Selecting A Manual Folding Machine:

When choosing a manual folding machine, consider the following factors to ensure it meets your specific needs:

- Material Compatibility: Ensure the machine can handle the thickness and type of paper you intend to fold.

- Folding Capacity: Assess the volume of folding you anticipate and select a machine that can comfortably accommodate your needs without excessive manual effort.

- Ease of Use: Look for straightforward machines with clear instructions and adjustable settings for different fold types.

Semi-Automatic Folding Machines

Semi-automatic folding machines represent a significant advancement in the paper and packaging industry. They bridge the gap between manual, labour-intensive processes and fully automated operations. These machines are designed to enhance efficiency, accuracy, and productivity in folding tasks, making them invaluable assets for businesses looking to optimise their operations.

Overview Of Semi-Automatic Folding Machines:

Semi-automatic folding machines require minimal manual intervention, primarily in feeding, where the operator needs to place the paper or material into the machine. The machine takes over once the material is fed, performing precise folds according to pre-set configurations. This hybrid approach combines the flexibility of manual machines with the efficiency of automatic systems, making it ideal for medium-sized operations that handle various folding tasks.

Key Features:

- Versatility: These machines can handle various paper sizes and types, from lightweight paper to heavy card stock, accommodating different industry needs.

- Precision: Semi-automatic machines offer precise control over fold types and sizes, ensuring consistent quality across batches.

- Efficiency: With faster folding rates than manual machines, semi-automatic models significantly reduce the time and effort required for folding tasks.

- User-Friendly: Many semi-automatic folding machines feature intuitive controls and settings, making them accessible to operators with minimal training.

Applications:

Semi-automatic folding machines are used in various sectors, including printing, packaging, and mailing services. They are particularly beneficial for:

- Small to medium print shops that require flexibility for different job types.

- Businesses that produce marketing materials, such as brochures and flyers, in-house.

- Packaging operations need efficient folding solutions for boxes, cartons, and other packaging materials.

Choosing The Right Machine:

When selecting a semi-automatic folding machine, consider the following factors to ensure it meets your specific needs:

- Capacity: Assess the volume of materials you need to fold to choose a machine that can handle your workload.

- Fold Types: Ensure the machine can perform the specific folds you require, such as letter folds, Z-folds, or custom configurations.

- Material Compatibility: Check that the machine can accommodate the paper weight and type you use.

- Ease of Setup and Operation: Look for machines with clear instructions and straightforward settings adjustments.

Fully Automatic Folding Machines

Fully automatic folding machines represent the pinnacle of efficiency and innovation in the paper processing and packaging industries. These machines are designed to handle the entire folding process with minimal human intervention, making them ideal for high-volume, high-speed operations where precision and consistency are paramount.

Overview:

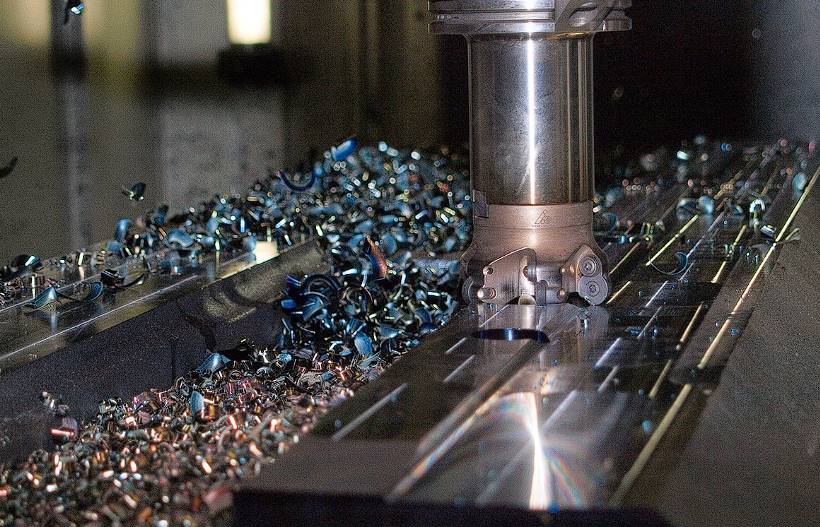

Fully automatic folding machines are equipped with advanced technology that allows for the automatic feeding, folding, and collecting of paper, cardboard, fabric, or other materials. These machines can perform a wide range of folds, including but not limited to letter folds, Z-folds, double parallel folds, and gate folds. With the ability to store multiple folding programs, these machines can easily switch between different folding tasks, making them incredibly versatile and suitable for various applications.

Key Features:

- High Productivity: Fully automatic folding machines significantly increase production rates by automating the folding process. They are capable of processing thousands of sheets per hour.

- Precision and Consistency: Equipped with precision-engineered components and sophisticated control systems, these machines ensure each fold is executed accurately, resulting in uniform output.

- Ease of Use: Despite their complexity, fully automatic folding machines are designed for ease of operation. They have touchscreen interfaces and programmable settings that allow operators to set up and modify folding tasks quickly.

- Versatility: These machines can handle various materials and sizes, making them suitable for various industries, including printing, packaging, textiles, and more.

Applications:

- Fully automatic folding machines are used in numerous sectors to enhance productivity and efficiency. Some typical applications include:

- Printing and Publishing: For folding brochures, pamphlets, leaflets, and other printed materials.

- Packaging: For folding carton boxes, inserts, and other packaging materials.

- Textile: For folding fabric, garments, and other textile products.

Choosing The Right Machine:

- When selecting a fully automatic folding machine, consider the following factors to ensure it meets your specific needs:

- Material Type and Size: Ensure the machine can accommodate the type and size of materials you intend to fold.

- Fold Types: Check that the machine can perform the specific folds required for your applications.

- Production Volume: Consider future growth by choosing a machine that can handle your production volume.

- Space and Budget Constraints: Consider the machine's footprint and your budget to ensure it fits within your operational constraints.

Specialty Folding Machines

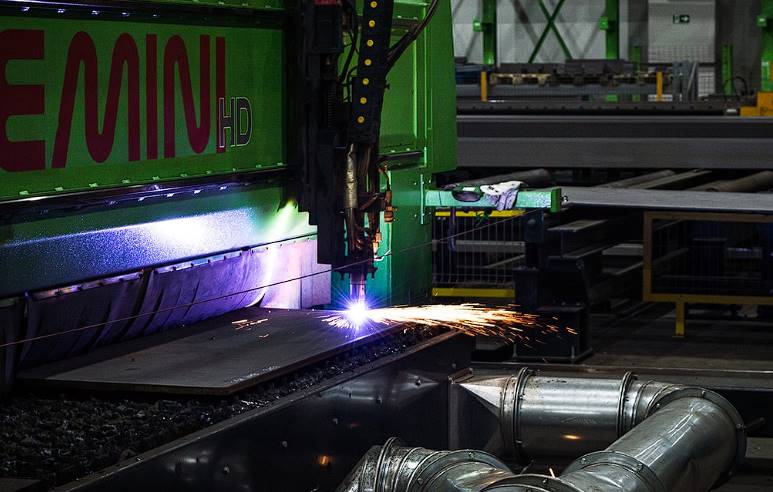

In the diverse world of folding and processing, specialty folding machines stand out for their ability to handle unique and complex tasks beyond the capabilities of standard folding equipment. These machines cater to specific needs, ranging from intricate pharmaceutical folds to large-format production and processing of unconventional materials. Understanding the nuances and applications of these specialised machines can significantly impact productivity and efficiency in various industries.

Pharmaceutical Folders:

Pharmaceutical folding machines are designed to create tiny and precise folds, often required for inserting instructions or information leaflets into pharmaceutical packaging. These machines typically feature four-fold plates, allowing them to perform up to four folds, significantly more than the standard two-plate folders. This capability makes them ideal for producing compact, neatly folded materials in small product packages.

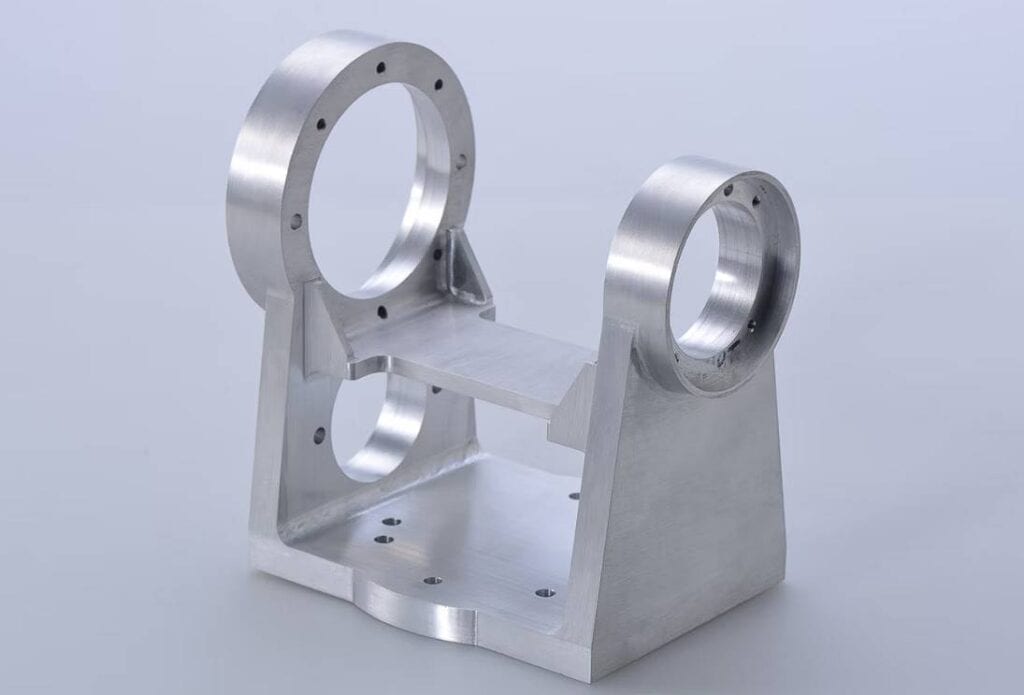

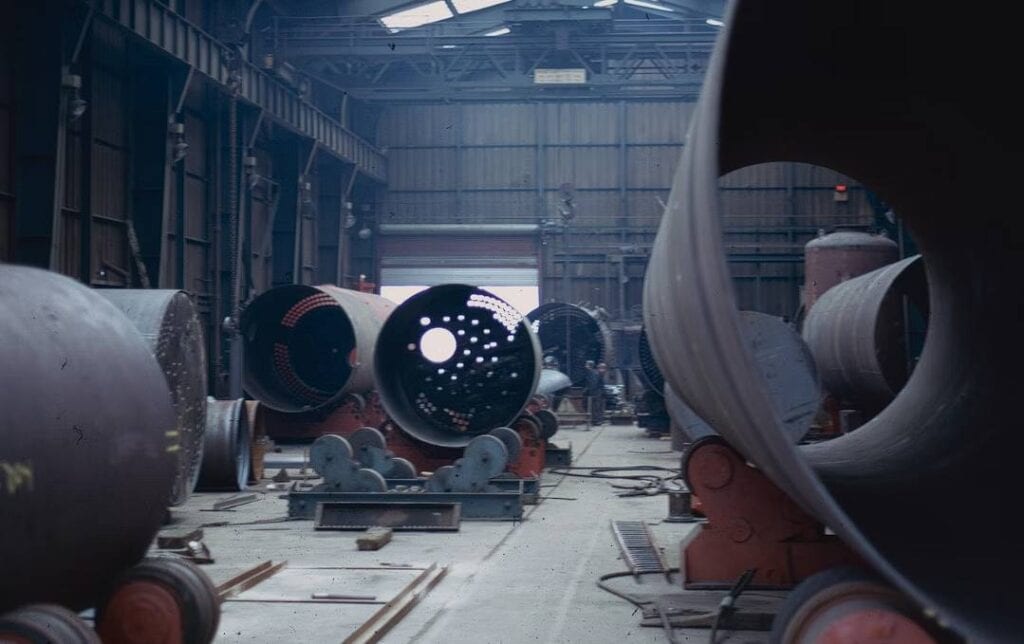

Specialised Folding And Processing:

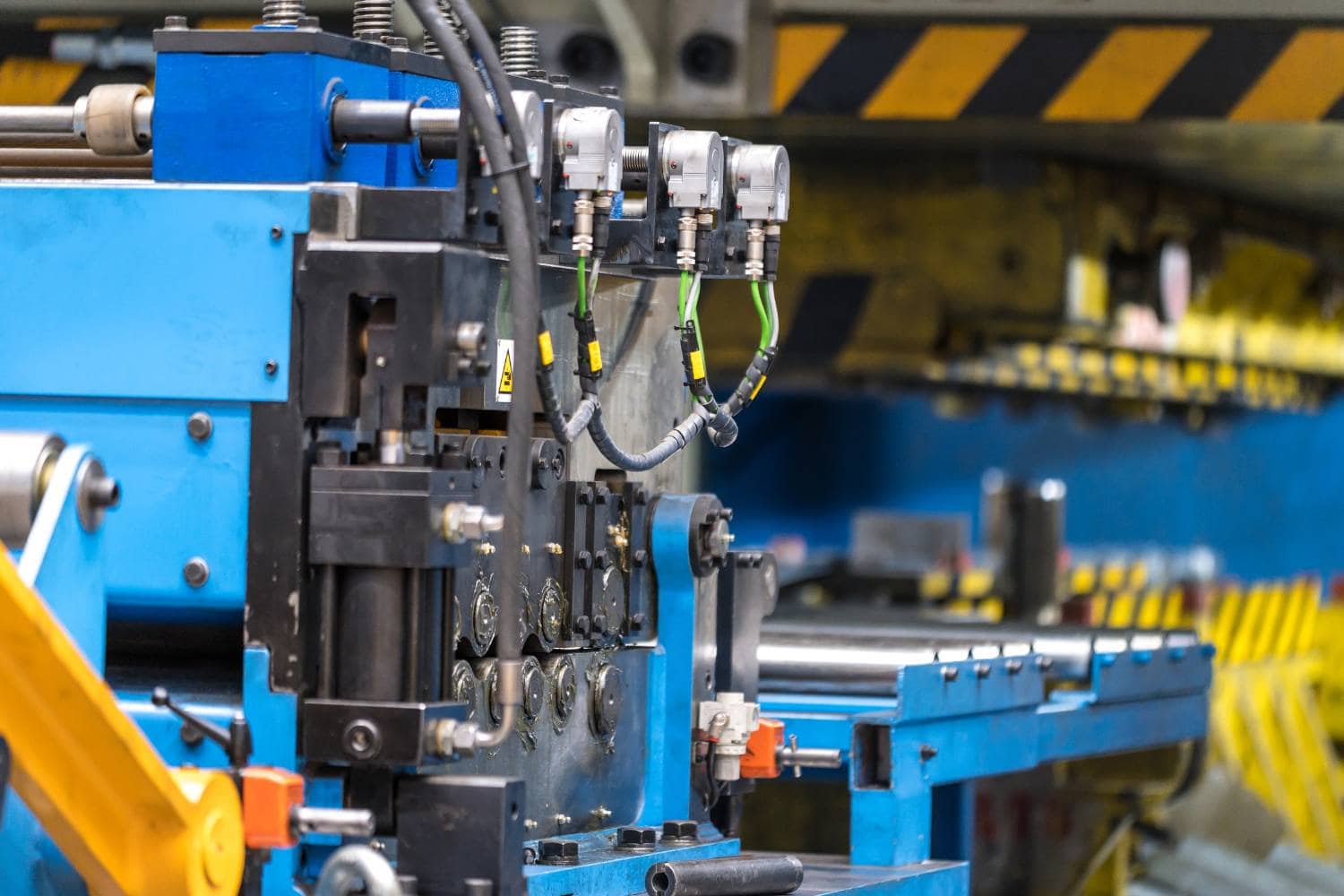

Beyond traditional paper folding, specialty machines cater to unique materials and processing needs. This includes machines capable of folding plastic film, fabric, and even metal sheets, each designed to overcome the challenges associated with these materials. For instance, air (vacuum) feed folding machines are preferred for handling glossy or slippery stock, ensuring smooth operation without the risk of jams or misfeeds.

Conclusion

Folding machines are essential tools in the print and paper processing industry. They transform flat sheets into precisely folded and beautifully folded products. They can be used to fold brochures, leaflets, letters, and booklets, among other documents. However, not all folding machines are equal, as each type has specialised functionality based on folding requirements, material types, and production volumes.

Manual folding machines are the most straightforward type of folding equipment, requiring the operator to feed and fold the paper physically. They are suitable for operations dealing with limited paper volume or where specific folds are crucial. They are portable, energy-efficient, and versatile, suitable for various applications, including marketing materials, educational pamphlets, and administrative documents.

Semi-automatic folding machines significantly advance the paper and packaging industry, bridging the gap between manual, labour-intensive processes and fully automated operations. They require minimal manual intervention, primarily in feeding, and offer precise control over fold types and sizes. They are efficient, user-friendly, and suitable for medium-sized operations that handle various folding tasks.

Semi-automatic folding machines are particularly beneficial for small to medium print shops, businesses producing marketing materials in-house, and packaging operations that need efficient folding solutions for boxes, cartons, and other packaging materials.

When choosing a folding machine, consider capacity, fold types, material compatibility, and ease of setup and operation. Semi-automatic folding machines can handle large materials, while fully automatic folding machines are designed for high-volume, high-speed operations. These machines can perform various folds, such as letter folds, Z-folds, double parallel folds, and gate folds. They are highly productive, precise, and easy to use, making them suitable for various industries.

When selecting a fully automatic folding machine, consider the material type and size, fold types, production volume, and space and budget constraints. Specialty folding machines can handle unique and complex tasks beyond standard equipment, catering to specific needs in pharmaceutical folds, large-format production, cross-fold systems, and processing unconventional materials.

Pharmaceutical folding machines are designed for small and precise folds, while large format machines can handle large-scale materials like posters and architectural plans. Cross-fold systems are necessary for projects requiring accurate and consistent cross-folds, and specialty machines cater to unique materials and processing needs, such as plastic film, fabric, and metal sheets. Air-feed folding machines are preferred for handling glossy or slippery stock, ensuring smooth operation without the risk of jams or misfeeds.

Content Summary

- Folding machines transform flat sheets into precisely folded products, ready for distribution or sale.

- They play a vital part in the production process across various industries.

- These machines can fold brochures, leaflets, letters, and booklets, among other documents.

- Not all folding machines are equal; each is designed for specific folding requirements and material types.

- The blog aims to explore the complex world of folding machines and their diverse applications.

- Whether in the printing industry, a business owner, or simply curious, the blog invites you to explore different types of folding machines.

- Each machine type serves a unique purpose, from manual folders to automated systems.

- Manual folding machines are basic but instrumental in creating neatly folded documents.

- They require the operator to feed and fold the paper physically.

- Suitable for operations with limited volume or specific fold intricacies.

- Manual machines are portable, energy-efficient, and versatile.

- They're ideal for small businesses, educational institutions, and home offices.

- When selecting a manual folding machine, consider material compatibility, folding capacity, and ease of use.

- Semi-automatic folding machines bridge the gap between manual and fully automated operations.

- They require minimal manual intervention, primarily in the feeding process.

- These machines are versatile, precise, efficient, and user-friendly.

- Suitable for small to medium print shops, in-house marketing material production, and packaging operations.

- Selecting a semi-automatic machine involves considering capacity, fold types, material compatibility, and ease of setup.

- Fully automatic folding machines are the pinnacle of efficiency and innovation.

- They handle the entire folding process with minimal human intervention.

- Capable of performing a wide range of folds and storing multiple folding programs.

- They offer high productivity, precision, consistency, and versatility.

- Typical applications include printing and publishing, packaging, and textile folding.

- Selection criteria include material and size, fold types, production volume, and operational constraints.

- Specialty folding machines cater to unique and complex tasks beyond standard equipment.

- Pharmaceutical folders create small, precise folds for packaging inserts.

- There are machines for both large and small-format paper production.

- Cross-fold systems are necessary for projects requiring cross-folds.

- Specialty machines also fold unique materials like plastic film, fabric, and metal sheets.

- Air (vacuum) feed folding machines are preferred for glossy or slippery stock.

- The diversity of folding machines enhances productivity and efficiency in various industries.

- Understanding the capabilities of these machines can significantly impact production processes.

- The blog provides insights into selecting the suitable folding machine for specific needs.

- It highlights the importance of folding machines in achieving high-quality finishes.

- The exploration of folding machines reveals their critical role in the manufacturing process.

- Manual folding machines offer a hands-on approach to paper folding.

- Semi-automatic machines combine flexibility with efficiency.

- Fully automatic machines are ideal for high-volume operations.

- Specialty folding machines address specific industry needs.

- The blog serves as a comprehensive guide to the world of folding machines.

- It encourages readers to consider the benefits of different machine types.

- The discussion on folding machines spans from basic to advanced technologies.

- The blog aims to demystify the complexities of folding equipment.

- Readers are invited to explore the technological advancements in folding machines.

- The versatility of folding machines is emphasised throughout the blog.

- The blog provides valuable information for professionals in the printing and packaging industries.

- It also caters to business owners looking to streamline their production of marketing materials.

- The exploration of folding machines is presented in an informative and engaging manner.

- The blog underscores the significance of selecting the appropriate folding machine.

- It concludes with an invitation to delve deeper into the capabilities and applications of folding machines.

Frequently Asked Questions

A folding machine is used in the printing and packaging industries to fold flat sheets of paper or other materials into specific shapes and sizes, ready for distribution or sale. These machines can handle various documents, including brochures, leaflets, letters, and booklets.

There are primarily four types of folding machines:

- Manual folding machines

- Semi-automatic folding machines

- Fully automatic folding machines

- Specialty folding machines

Each type serves different operational needs and production volumes.

Manual folding machines require the operator to feed and fold the paper physically. They are suitable for operations with limited volumes or specific folding intricacies. These machines are ideal for small businesses, educational institutions, and home offices that need to fold documents occasionally.

Semi-automatic folding machines can handle various paper sizes and types, from lightweight paper to heavy card stock. They are designed to enhance efficiency, accuracy, and productivity with minimal manual intervention.

Fully automatic folding machines are designed to handle the entire folding process with minimal human intervention, making them ideal for high-volume, high-speed operations. They are equipped with advanced technology that allows for automatic feeding, folding, and collecting of materials.