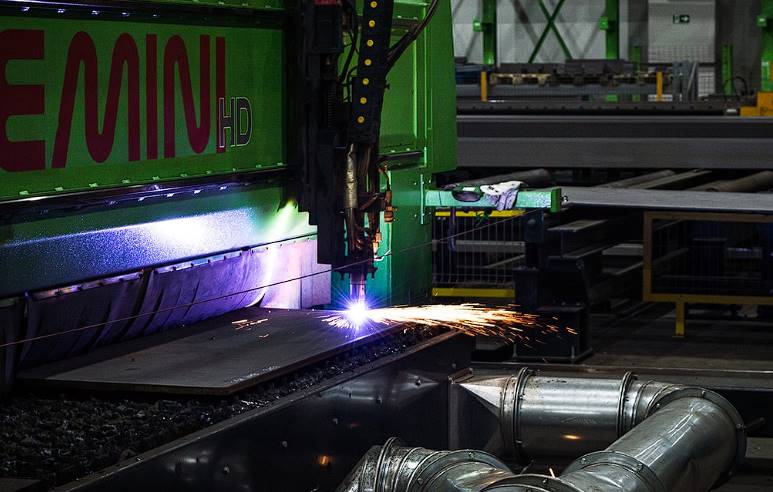

Laser cutting is a technology that is widely utilised in a variety of industries. This cutting method offers both precision and efficiency when slicing through various materials. It is of the utmost importance to be aware that, similar to any other procedure, laser cutting presents its own set of potential dangers and risks.

In this blog, we will look into the different dangers that are associated with utilising laser cutting, as well as explain the most efficient ways to protect against them. You can create a risk-free working environment for yourself and your colleagues if you are aware of the potential hazards in the workplace and take the necessary precautions to protect against them.

What Is Laser Cutting?

Let's start by providing a high-level overview of what goes into laser cutting before delving into the potential dangers that go along with it. The process of laser cutting involves passing a powerful laser beam through various materials, including metal, plastic, wood, and fabric, to create cuts in them.

Along the path of the predetermined cutting line, the laser beam is concentrated and directed onto the substance, which causes the material to melt or vaporise. Because it provides accurate, intricate, and clean cuts, this method is extremely desired in industries.

Hazards Of Laser Cutting

Uncontrolled laser beams, inadequate ventilation, and combustible materials are the most typical causes of laser safety incidents.

Common risks associated with laser cutters include:

Eye Damage

When a laser beam reaches the eye, it can burn the retina, causing permanent vision loss. Depending on the wavelength, this might cause problems with the eyes' retina, cataracts, and cornea. The greater the laser's intensity, the greater the risk it poses.

It's important to keep in mind that lasers can cause eye damage even if you don't look directly at the beam. It is possible for Class 3B and Class 4 lasers' reflected light to enter and injure the eye.

Thus, laser safety glasses must always be worn when working with lasers. Ensure the laser is safely enclosed and all its safeguards are operational. When the machine's cover or door is opened, the laser is automatically shut off via safety interlocks.

Fires

When used on combustible materials, laser cutters pose a fire hazard. The laser beam can fire the material and everything else nearby if its energy needs to be carefully managed. Only materials that a laser can cut should be placed on the laser bed to eliminate a potential fire hazard. Certain materials also necessitate additional precautions. Laser cutting shouldn't be done on materials like PVC, which release dangerous vapours when burned.

Noise Exposure

In some cases, the noise levels generated by a laser cutting machine may be too high for safe workplace use. Long-term exposure to loud noise has been linked to a variety of aural health issues, including hearing loss. Noise levels can be reduced, and engineering measures like soundproof enclosures and earplugs can protect operators' and nearby workers' hearing.

Skin Burns

The high-energy light emitted by laser cutters poses a risk of severe skin burns. Contact with the laser beam causes painful burns because it warms the tissue to the point of destruction or combustion.

More powerful lasers and those of specific wavelengths that are more readily absorbed by the skin increase the risk of skin burns. To reduce the likelihood of skin burns when using laser-cutting machines, it is crucial to take the necessary precautions, such as wearing protective clothes and following safety standards.

Shock And Electrical Failure

Very high voltages are needed for laser-cutting machinery. An electrical shock could result if the laser's housing is damaged or its inner workings are exposed. The risk level can be reduced by performing routine checks on the housing and fixing any broken parts right away.

Significant health and safety concerns are at play here; you must ensure the safety of your employees and the premises at all times by keeping a close eye on your equipment.

Wounds And Cuts

When using a laser cutter, it is important to take precautions to avoid getting cut on the sharp edges of the substance being cut or the moving elements of the laser cutter. Laser cutting, while unrelated to the laser beam itself, can result in a material with sharp or pointed edges. They may cause slicing or puncturing injuries.

To avoid injury, use extra precautions when handling cut objects, especially right after cutting when edges are at their sharpest.

Protect yourself further by using protective gear like cut-resistant gloves. Users should also be aware of the machine's moving parts and avoid putting their hands or fingers in dangerous places.

Inhalation Of Particles And Fumes

Dangerous gases and particles can be emitted into the air while laser cutting certain materials, such as plastics or metals. Breathing in these vapours or dust might aggravate or even cause respiratory difficulties. Proper ventilation systems, such as local exhaust ventilation, must be in place to rid the workplace of these toxins. To further reduce the possibility of inhalation, it is suggested that people wear masks or respirators.

Important Laser Cutting Safety Precautions

Using a laser cutter requires careful attention to safety measures. Accidental exposure to the powerful laser can result in irreversible vision loss. Therefore, getting the right training, putting on the right protective gear, and never disabling the machine's safety interlocks is crucial. In addition, there is always a need for fire safety measures to be taken when laser cutting.

Important safety measures for laser cutting are as follows:

Never Disable Cutter Safety Interlocks.

Laser cutters would only be usable with the built-in safety features. Class-3B or Class-4 lasers are typically used. Direct or even indirect exposure to these classes can be harmful to the eyes, and they also can burn skin and start fires.

Nonetheless, due to the safety features integrated into the laser cutter, it is typically sold as a Class-1 laser device. It means they're up to code with regard to keeping users away from the laser's potentially lethal radiation. The lid of the machine is often the first line of defence, being interlocked such that the laser cannot fire if the lid is open.

If this safety mechanism is turned off or tampered with, a harmful laser that could damage your eyes or skin could be released.

Do Not Leave An Operating System Running Unattended.

When laser cutters are left unattended, they might cause fires if they strike combustible materials or if the wrong settings are employed. For this reason, any time a laser cutter is in use, close monitoring is required. You can immediately put out any fires that could break out if you keep an eye on the cutting process.

In addition, a fire extinguisher should always be within easy reach in case of an emergency. These safety measures ensure that any flames may be put out quickly, reducing the risk of injury or death.

Maintain A Record Of Laser Cutter Users, Cutting Time, And Materials Cut.

Keeping track of who has been cutting what and when in a logbook may be crucial. The residue left behind by some materials could be combustible. In addition, the previous operator can be contacted if the new user notices anything strange when inspecting the cutter. Keep track of how many hours the laser is used so that maintenance can be scheduled in advance.

Keep The Laser Away From Your Eyes Directly.

The sensitive ocular tissues could be severely damaged if the eyes are exposed directly to the laser cutting beam. Brief exposure to the laser beam can result in short-term blindness or other eye problems. Consequently, it is always critical to put laser safety first.

This necessitates the use of protective eyewear developed for use with lasers. Using protective eyewear when using a laser cutter is the best way to keep your eyes safe and preserve your eyesight over the long haul. Keep in mind that eye safety is paramount whenever dealing with lasers.

Learn Which Materials Can Be Cut Safely

A laser cutter should not be used to cut through certain materials. In most cases, they provide a significant fire hazard, or their interaction with the laser produces hazardous gases. Before you start cutting, it's a good idea to do some research on each material. PVC plastic is an example of a harmful material. The polymer breaks down into hydrogen chloride gas when sliced by a laser. Hydrochloric acid is produced when this comes into contact with water, as in a person's eyes or lungs.

Use Effective Cooling To Control Laser Heat.

In most cases, laser cutting equipment will require cooling to prevent damage from overheating and malfunctioning when utilised in a hot environment.

Ventilation and heat management are crucial while using a laser cutter. In order to keep the laser tube from overheating, certain laser cutters come equipped with cooling systems, such as water cooling in CO2 laser cutters.

On the other hand, there are problems that might arise from being excessively cold. For instance, a laser tube cooled by water could break if the water suddenly freezes.

Discover How Laser Pulse Rate Affects Fire Risk.

Laser cutters use pulp firing patterns to boost the maximum optical power output. A pulsed laser is one that emits intense bursts of energy rather than a steady stream. The laser can "store" energy between pulses, producing higher power with a given frequency. If the pulse frequency is increased, the peak energy will also decrease. As a result, there is a greater potential for fire to start in the material being cut at lower pulse frequencies.

Avoid Debris With The Laser.

Debris and dust from the laser cutter constitute a major fire risk if they collect in the area around it. All it takes is for these particles to come into touch with the laser beam or the heat it creates for them to catch fire. Debris like this can also hinder the machine's performance and cause it to break or wear out prematurely.

The cutting bed and the region around the laser should be cleaned frequently, as well as the rest of the workspace and the machine itself. The longevity and efficiency of your laser will both increase as a result of this.

Cutting areas with an effective exhaust system have better air quality for workers and lower fire risks.

Ensure You've Received The Appropriate Training

Learning the ropes before firing up the laser cutter is a must. As laser cutters contain multiple potentially dangerous parts, it's crucial to appreciate the dangers they pose fully. The device's maker may be able to offer customised instruction in many circumstances.

The general dangers of laser cutting and the specifics of the machine itself, such as its operating protocols and safety interlocks, should be covered in such seminars. New operators must receive extensive training and periodically revisit their training to ensure they are up-to-date on the latest best practices and safety protocols. Operators can reduce potential dangers and maximise laser cutter productivity through dedicated training.

Follow The Laser Cutter Manufacturer's Directions

The laser cutter maker is aware of the machine's shortcomings and potential dangers. Each laser cutter will have safety features and interlocks to protect its users and machinery. When purchasing a new cutter, it is imperative that you familiarise yourself with its operation and safety procedures.

It's crucial to pay attention to and adhere to the manufacturer's instructions and recommendations, especially if they specify limits or indicate any potential dangers. If you don't follow the instructions, you could hurt yourself or others, void the warranty on your equipment, or even get fired from your job.

Stay Alert

It is crucial to always stay alert when using a laser cutter. It is essential to have one's wits about oneself and avoid becoming complacent, as accidents can and do happen when users lose focus or ignore safety measures. Focusing on the job and being aware of potential dangers will greatly lessen the possibility of an accident.

In addition, the laser cutter should always be supervised for long periods of time. If any problems arise with the machine, they may be fixed quickly, reducing the likelihood of injuries or property loss. In order to maintain a risk-free workplace around laser cutters, employees and supervisors must pay close attention.

What Safety Equipment Is Needed For Laser Cutting?

When using a laser cutter, wearing protective eyewear, a face mask or respirator, and heavy gloves is important. The lenses of laser safety glasses are darkened in such a way as to absorb any laser light that may otherwise reach the wearer's eyes.

The glasses should be compatible with the specific brand and wavelength of the laser. In addition, their hues vary from laser to laser based on the wavelength of light they are designed to absorb, with diode lasers being blue or green, CO2 lasers being grey, and fibre lasers being pale green.

Another vital protective equipment is a respirator (a cartridge mask, like the ones used by painters). The operator may need to wear respiratory protection regardless of the extraction mechanisms in place and the nature of the material being cut. It's important to use cartridges that will keep you safe from the fumes released by the material being cut. They are often organic vapours of some kind.

When working with freshly cut materials, thick gloves might be helpful because of the heat they absorb.

Is There A Safety Program For Laser Cutting?

Several laser-cutting safety systems are currently on the market. If you want to know which courses are compatible with your machine, contact the company that made it. If that isn't possible or they don't have any helpful suggestions, you can likely find a laser-cutting expert who can instruct you on how to use the machine safely.

How Can I Prevent Laser Fumes From Entering My Lungs?

The most important thing to do to avoid breathing in harmful fumes from laser-cutting materials is to have an extraction system set up and functioning. Most laser cutters incorporate an exhaust system to prevent the buildup of smoke and dust. Typically, it will suck air up from below the work surface. A hood can be placed over the laser cutter as a secondary extraction system. As a result, any exhaust gases within the machine's housing will be eliminated.

Choose your cutting material with caution to reduce exposure to harmful fumes. Find out ahead of time what kind of gases will be produced by cutting certain materials, and try to avoid using anything dangerous. For instance, the discharge of hydrochloric gas during the melting and decomposition of PVC plastic makes it unsafe for laser cutting.

Finally, you can prevent lung damage by using a respirator mask equipped with Featuring cartridges that absorb moisture while filtering the air from the pollutants before you breathe them in. Choose a cartridge suitable for organic vapours if you plan on cutting organic materials.

Conclusion

Laser cutting is a widely used technology in various industries, offering precision and efficiency in cutting materials. However, it presents its own set of potential dangers and risks. Common risks associated with laser cutting include eye damage, fires, noise exposure, skin burns, shock and electrical failure, wounds and cuts, and inhalation of particles and fumes. Eye damage can result from the laser beam burning the retina, cataracts, and cornea, while fires can occur when used on combustible materials. To reduce these risks, it is essential to wear laser safety glasses, ensure the laser is safely enclosed, and use safety interlocks to shut off the laser when the machine's cover or door is opened.

Fires pose a significant risk to laser cutters, as they can fire the material and nearby materials. Only materials that can be cut should be placed on the laser bed, and certain materials, like PVC, should be avoided. Noise levels can be reduced by using soundproof enclosures and earplugs. Skin burns are another risk, as the high-energy light emitted by laser cutters can cause painful burns. Proper ventilation systems, such as local exhaust ventilation, must be in place to rid the workplace of these toxins.

To ensure safety, it is crucial to have the right training, protective gear, and never disabling the machine's safety interlocks. Class-3B or Class-4 lasers are typically used, but they are typically sold as a Class-1 laser device due to their safety features. If the safety mechanism is turned off or tampered with, harmful lasers could be released.

Local monitoring is necessary when using laser cutters, as they can cause fires if they strike combustible materials or use incorrect settings. Regular monitoring and safety measures are essential to create a risk-free working environment for both employees and the environment. A fire extinguisher is essential for emergency situations, as it helps quickly extinguish flames and reduces the risk of injury or death. It is crucial to keep a logbook of laser cutter users, cutting time, and materials cut to ensure proper maintenance. Protective eyewear is essential for eye safety and preventing eye damage.

To cut safely, it is essential to research materials that can be cut safely, such as PVC plastic, which can cause short-term blindness or other eye problems. Laser cutters use pulsed lasers to boost the maximum optical power output, but increasing the pulse frequency can decrease the peak energy, increasing the risk of fires.

Debris and dust from the laser cutter pose a major fire risk, and cleaning the cutting bed, surrounding area, and the machine itself can improve the laser's longevity and efficiency. Ensure that new operators receive appropriate training to understand the risks and ensure proper operation.

The laser cutter manufacturer's instructions and recommendations should be followed when purchasing a new cutter. It is essential to follow these instructions to avoid injury or job loss.

Staying alert and following manufacturer's instructions is crucial for maintaining a risk-free workplace around laser cutters. Wearing protective eyewear, a face mask or respirator, and heavy gloves is essential. Laser safety glasses should be compatible with the specific brand and wavelength of the laser, and respirators should be used to protect the operator from the fumes released by the material being cut.

In conclusion, proper safety measures and proper training are essential for using laser cutters safely. Proper safety equipment, such as protective eyewear, face masks, and respirators, is essential for maintaining a safe and efficient work environment. To ensure safety while working with laser-cutting materials, wear thick gloves to protect your hands from heat. There are various safety programs available, but it's crucial to have an exhaust system in place to prevent harmful fumes from entering your lungs. Choose the right cutting material and avoid using dangerous materials, such as PVC plastic, which can release hydrochloric gas. Additionally, use a respirator mask with cartridges that absorb moisture and filter pollutants before breathing, especially for organic materials.

Content Summary

- Laser cutting is a technology widely used in various industries for its precision and efficiency.

- Laser cutting presents its own set of potential dangers and risks that need to be addressed.

- Eye damage is a significant risk when exposed to laser beams, even if not directly.

- Fires can occur when laser cutters are used on combustible materials.

- Noise exposure from laser cutting machines can cause hearing loss.

- High-energy laser beams can cause severe skin burns.

- Electrical failure and shocks are possible due to the high voltages used in laser-cutting machinery.

- Precautions should be taken to avoid wounds and cuts from sharp edges.

- Inhalation of particles and fumes emitted during laser cutting can cause respiratory difficulties.

- Important safety precautions include not disabling cutter safety interlocks and not leaving the operating system unattended.

- Keeping a record of users, cutting time, and materials is crucial for safety and maintenance purposes.

- Protective eyewear is essential to prevent direct exposure of the eyes to laser beams.

- Proper training and adherence to manufacturer's instructions are necessary for safe laser cutting.

- Staying alert and avoiding complacency while using laser cutters is crucial.

- Safety equipment such as protective eyewear, face masks or respirators, and heavy gloves are needed for laser cutting.

- Extraction systems and ventilation are essential to prevent inhalation of harmful fumes.

- Researching materials to ensure safe cutting and using appropriate cartridges in respirator masks can prevent lung damage.

- Safety programs and training can provide guidance on using laser cutters safely.

Frequently Asked Questions

To ensure a safe working environment for laser cutting, it is crucial to implement a combination of engineering controls, administrative measures, and personal protective equipment. This includes providing adequate ventilation, maintaining equipment regularly, conducting risk assessments, training, and enforcing strict safety protocols.

Laser cutting is known for its precision and clean cuts. However, when exposed to the laser beam, certain materials may be prone to thermal damage or discolouration. Testing the laser cutting parameters on a small material sample is important to ensure the desired outcome without compromising its integrity.

Yes, different materials may require specific laser-cutting guidelines to achieve optimal results. For example, metals may require different laser power settings than plastics or fabrics. Consult the material manufacturer's recommendations or seek guidance from laser cutting experts to determine the appropriate parameters for different materials.

Regular maintenance is crucial to ensure a laser-cutting machine's safe and efficient operation. Follow the manufacturer's recommended maintenance schedule, which typically includes cleaning the optics, inspecting the laser beam path, and checking the cooling system. Regular maintenance helps identify and address potential issues before they escalate into safety hazards.

Using a laser cutter at home is safe if you follow a safe operating procedure. Users should also always be aware of how to prevent laser hazards by wearing protective gear, avoiding direct eye contact with the laser, and using laser cutter-safe materials only.