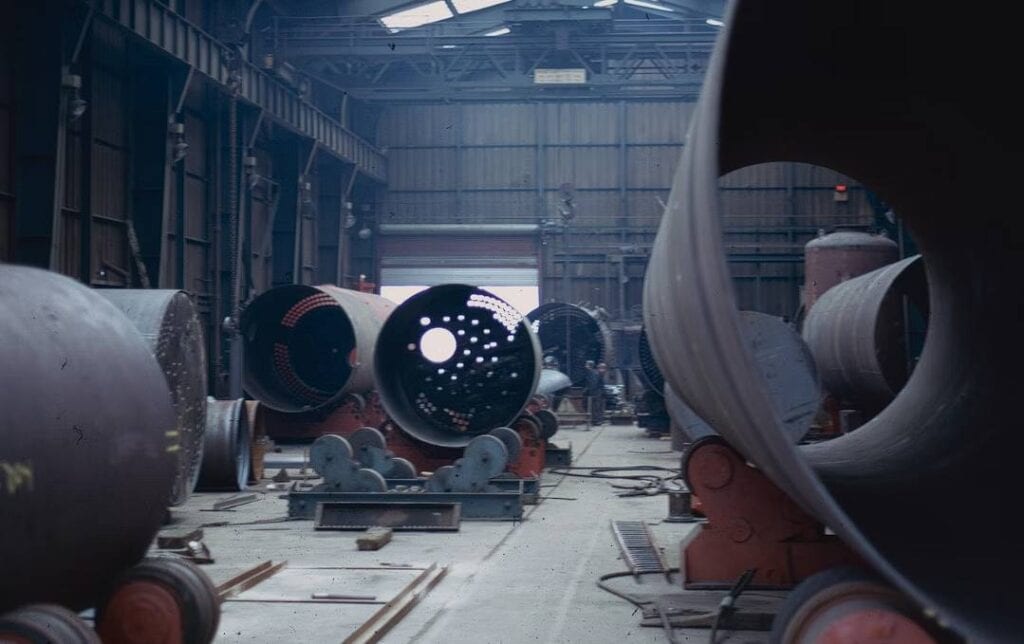

Welding is a highly specialised profession that is essential in many fields, including production, building, transportation, and aerospace. It's the process of joining metal parts with heat and pressure to form permanent joints. However, success in welding requires more than just the ability to fuse metal together.

To become a competent welder, one needs a wide range of skills, including technical knowledge, safety awareness, the ability to solve problems, the knack for communicating effectively, and so on. Welders need these abilities to do their jobs well, keep their workplaces safe, and turn out quality welds.

In this detailed blog, we'll learn everything you need to know to get started welding. We will investigate the technical abilities required to use welding machinery, read blueprints, and comprehend the characteristics of various metals. We will also stress the importance of safety awareness to ensure the safety of the welder and those around them.

What Kind Of Skills Are Required To Be A Welder?

First, the welder studies the blueprints and determines the appropriate measurements for cutting and assembling the metal parts.

The construction and manufacturing sectors account for the vast majority of their workforce. Welders play a crucial role in manufacturing a wide variety of ships, cars, planes, and buildings. They can also be used to repair metal by filling holes, cracks, and dents.

Employers prefer candidates with at least some work or technical experience and a high school diploma. However, many welders opt to prove their competence through certification.

A certificate or degree may not be required, but having one on your resume never hurts. In addition to courses in blueprint reading, mechanical drawing, and related topics, students would do well to study physics, chemistry, and metallurgy.

Those interested in becoming welders might start by working as an apprentice in the trade.

How do you feel about working eight hours a day at a desk? Do you seek a career that will let you set your own goals and develop at your own pace? You may change careers due to growing dissatisfaction with your current position.

Welding may not have been their first career choice, but it's a great option for people looking to change. Almost anyone can learn the skills necessary to become a welder.

Those who are enthusiastic about this area of study can choose from many different career paths. Your level of effort is entirely up to you.

A high school diploma from a recognised institution and some work experience will get you far in life. Still, welders have options that could take them abroad and land them well-paying jobs. With the right set of skills, virtually anyone can break into the welding industry.

Types Of Welding Skills

As a result of the fact that employers are looking for welders who can meet their requirements, it is essential to place emphasis on possessing the appropriate skills throughout the hiring process.

Mathematical Skills

Those who are also good with numbers are in high demand among welders. Reading blueprints, comprehending designs, and estimating welding proportions are necessary. Cutting and trimming metal to exact specifications calls for a head for numbers.

Welding is a field where precise measurement is of paramount importance. You will use your mathematical skills every day as a welder, from reading blueprints to calculating the length of a joint and the strength of a weld.

An understanding of mathematics is essential for the calibration of equipment. If you could improve at mathematics or it has been a while since you studied the subject in school, you may want to take a refresher course, buy a book, or sign up for some maths refresher courses at the community college in your area.

If you want to learn how to weld like a pro, it helps to have a good head for numbers. You'll be a more valuable employee if you can do simple calculations, read plans, and understand two- and three-dimensional diagrams.

A welder's ability to calculate the dimensions needed to cut metal to size is a valuable skill.

If you are good with numbers, it will benefit you greatly in your work, both generally and specifically.

- Reading Drawings

- Calculating Size

- Plans Interpretation

- Using Logic in Two and Three Dimensions

Physical Capabilities

Generally, welders should be in decent shape to do their jobs well. Because of the job's physical demands, welders frequently face difficult working conditions, including long periods of standing, carrying heavy objects, and contorting their bodies in awkward ways to get into working positions.

They must also maintain a firm grip on their torches while holding them in place for extended periods of time, which calls for a steady hand and a strong grip.

The most important physical abilities for the job are:

- Dexterity

- Good vision

- Steady hands

- Physical endurance

- Physical strength

- Hand-eye coordination

- Good mobility and flexibility

Educational Skills

Welders are often expected to have some college education. This is because you need to understand the basics of mathematics and physics.

Skills in reading blueprints, determining material needs, determining material costs, measuring, forming joints, understanding angles, calculating pressure changes, and evaluating weld strength are all necessary.

A profound understanding of welding theory, the composition of materials, and the intricate interplay between different metals and materials is imperative to produce exceptional welds.

Additionally essential for academic success are the following skills:

- Ability to perform elementary maths

- It is essential to work with decimal and fractional measurements and convert between them.

- Understanding the fundamentals of algebra

- Chemistry 101

- Elementary geometry theorems

- A trigonometry primer

- Primitive physics

Attention To Detail

In most cases, a welder's effectiveness depends on their innate or learned ability to detect even minute details. Welders must be especially careful when working on bridges, aeroplanes, and ships because mistakes could endanger lives. It is also crucial for welders to be aware of their surroundings when working in potentially hazardous environments.

Paying close attention to detail requires a variety of important skills, including:

- Precision cutting ability

- The ability and willingness to constantly inspect all materials

- The ability to follow safety procedures and guidelines

- The practice of keeping clean workspaces

- The ability to follow instructions precisely

- The skill and familiarity with detecting changes in metal flows that is necessary

Personal Skills

Being a welder is very different from being an office worker. Carrying heavy objects and dealing with occasionally unpleasant working conditions make welding a physically demanding occupation.

You'll need the following bodily capabilities to begin welding. Expertise in management, inspection, or engineering reduces the need for strenuous physical labour.

These skills will serve you well in any career, not just in welding. Working with others, seeking employment, and furthering your education are all things you'll have to do at some point.

You've toyed with the idea of starting your own business, and now you've come to the realisation that you need to hire people to run it.

- Self-motivated

- Teamwork

- Accurate

- Efficiency in organising

- Dependable; trustworthy

- Capability to Manage Time

- The ability to express oneself clearly

- Capability to provide high-quality records of completed tasks

- Having the ability to focus and pay attention in class (safety standards and protocols)

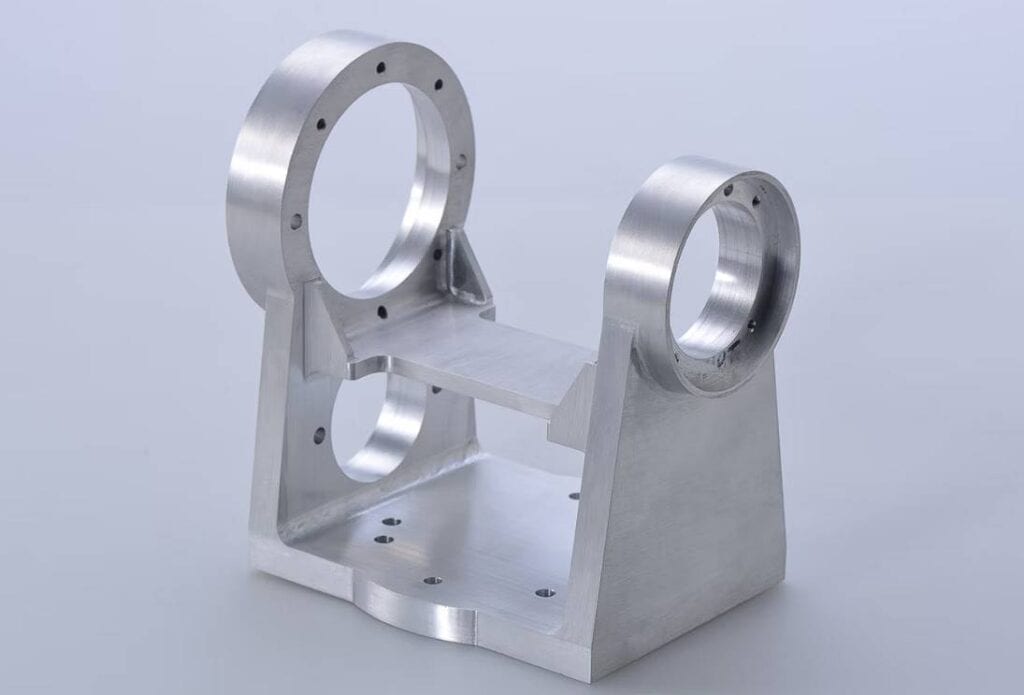

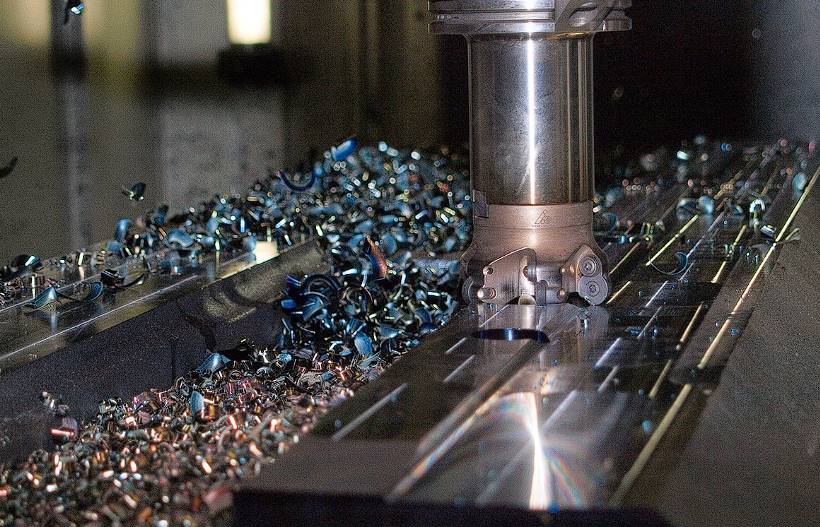

Technological And Tool-Handling Skills

Welders get their hands dirty on a wide range of projects, each with unique challenges. To be successful as a welder, you need to be well-versed in a wide variety of technological tools and devices, know how to determine which tool is best for a given situation, and then use that tool to its full potential. Welders need to have a variety of technological competencies, including but not limited to:

- Learning new technologies and practises

- Skills with robotic welding equipment

- Possessing the skills necessary to assemble machinery and take it apart again after use

- Knowledge of hand tools

- Expertise in using grinding machines and metal finishing techniques

- Having the expertise to know which resources to use in any given circumstance.

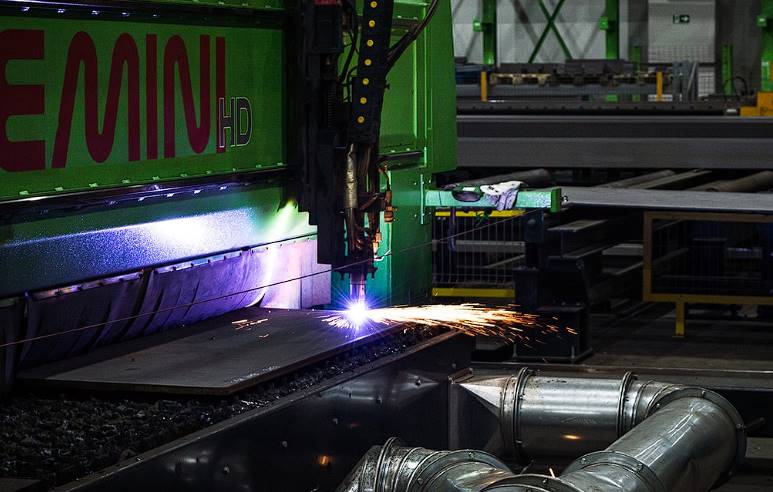

Knowledge Of Different Welding Techniques

Even when apprenticeship programmes are available, many businesses still prefer to hire experienced welders. These experts are deeply familiar with a wide range of welding methods that allow them to perform at a high level in their field. Popular welding processes include MIG (metal inert gas), TIG (tungsten inert gas), stick, and flux-core, but some occupations and fields call for more specialised training.

Welders can increase their marketability and enter new fields by learning specialised welding techniques. Learning the welding techniques that will be most useful in a given field is a good idea if you're planning a career in that field.

Capability To Carry Out Related Fabrication Tasks

Although welding is an important part of a welder's job, it's just one of many tasks they perform. They may also perform torch-cutting, grinding, bevelling, simple soldering, and brazing, among other related tasks. Their adaptability and market value will increase thanks to these newly acquired abilities.

To develop into a highly sought-after welder, it is essential to master these various skills. Welders who can easily switch between tasks and methods demonstrate their skill and versatility, making them invaluable in fields where this knowledge is in demand. Welders can set themselves apart from the competition and prove their worth by constantly developing their skills.

Physical Endurance And Strength

The job's physical demands make it essential that welders have robust bodies and the mental fortitude to stick it out in the face of adversity. It is not uncommon for welders to routinely carry loads weighing fifty to one hundred pounds or more, depending on their speciality.

Welders need mental toughness and physical stamina because they often must stand in one place for long periods. It's important for welders to have strong mental and physical fortitude because they may frequently have to work in less-than-ideal weather conditions.

Excellent Work Ethics

Welding is no different from any other field in that dedication is crucial to success. People rely on you to get things done in a timely manner, and that includes both customers and coworkers. A single worker's lackadaisical efforts can have a major impact on the overall productivity of a construction site.

This is why a strong work ethic is regarded as one of the most admirable qualities in a person. Taking pride in your work is good for your professional standing and the welding industry as a whole.

Good Teamwork And Communication Skills

It is important for welders to be able to work well with others and communicate effectively, as even though they may work on individual pieces independently, most welding projects are part of a larger whole.

It would be best if you were a dependable worker who asks questions and gets answers, helps out teammates, uses their time efficiently, and gets along well with others. Having these abilities will make you an invaluable member of any welding team.

What Is The Distinction Between A Skilled Welder And An Unskilled Welder?

The construction and manufacturing industries are two of the most common users of welders and welders as a trade. Not all welders are employed in professional settings.

The training requirements for certain types of welding jobs are more stringent. Welders, in general, can be classified into one of these two categories:

- Skilled welder. A qualified welder will learn their craft via an apprenticeship and be well-versed in metals, heat reactions, reading blueprints, and welding techniques. They can work independently, complete a wide range of welding tasks, and diagnose and fix welding problems.

- Unskilled welder. An unskilled welder has had less formal training and can only perform a few basic welding procedures. They could also help out a skilled welder as an assistant.

Knowing what both experienced and inexperienced welders do can help determine what training you'll need to enter the field.

Conclusion

Welding is a highly specialized profession that involves joining metal parts with heat and pressure to form permanent joints. To become a competent welder, one needs a wide range of skills, including technical knowledge, safety awareness, problem-solving, and effective communication. Welders play a crucial role in manufacturing various types of ships, cars, planes, and buildings, as well as repairing metal by filling holes, cracks, and dents.

Employers prefer candidates with at least some work or technical experience and a high school diploma. Many welders opt to prove their competence through certification. Students should also study physics, chemistry, and metallurgy.

Welders can start by working as an apprentice in the trade. They can choose from many different career paths, and with the right set of skills, virtually anyone can break into the welding industry.

Mathematical skills are essential for welders, as they read blueprints, understand designs, and estimate welding proportions. They must also be in good physical condition to perform their jobs well, such as flexibility, good vision, steady hands, physical endurance, physical strength, hand-eye coordination, and good mobility and flexibility.

Educational skills are also essential for welders, as they need to understand the basics of mathematics and physics. They must be able to read blueprints, determine material needs, determine material costs, measure, forming joints, understand angles, calculating pressure changes, and evaluating weld strength.

Attention to detail is crucial for welders, as mistakes can endanger lives and require close attention to detail. Welders must be careful when working on bridges, aeroplanes, and ships, as mistakes can endanger lives.

Personal skills are also important for welders, as they carry heavy objects and face unpleasant working conditions. They need to be self-motivated, teamwork, accurate, efficient in organizing, dependent, trustworthy, time management, clear self-expression, ability to provide high-quality records of completed tasks, and focus on safety standards and protocols.

Technological and tool-handling skills are also essential for welders, as they work on a wide range of projects with unique challenges. These skills will serve you well in any career, not just welding. Welders are essential professionals in various fields, including assembling machinery, hand tools, grinding machines, and metal finishing techniques. They possess knowledge of various welding techniques, such as MIG, TIG, stick, and flux-core, and can increase their marketability and enter new fields by learning specialized techniques. They can also perform related fabrication tasks, such as torch-cutting, grinding, bevelling, soldering, and brazing, which demonstrate their versatility and market value.

Physical endurance and strength are crucial for welders, as they often carry loads weighing 50 to one hundred pounds or more. They need mental toughness and physical stamina to stand in one place for long periods, especially in less-than-ideal weather conditions. A strong work ethic is a admirable quality in a person, as it demonstrates dedication to their work and the overall productivity of a construction site.

Good teamwork and communication skills are essential for welders, as most projects are part of a larger whole. A dependable worker who asks questions, helps teammates, and uses their time efficiently is an invaluable member of any welding team.

The distinction between skilled and unskilled welders is that skilled welders are well-versed in metals, heat reactions, blueprints, and welding techniques, while unskilled welders have less formal training and can only perform basic welding procedures. Understanding the differences between experienced and inexperienced welders can help determine the necessary training for entering the field.

Content Summary

- Welding is essential in various fields, including production, building, transportation, and aerospace.

- Welding involves joining metal parts with heat and pressure to create permanent joints.

- Success in welding requires a wide range of skills, not just fusing metal together.

- Technical knowledge is essential for using welding machinery and understanding metal characteristics.

- Safety awareness is crucial for maintaining a safe workplace and preventing accidents.

- Problem-solving skills are necessary for addressing welding challenges.

- Effective communication is essential for collaboration and understanding project requirements.

- Welders can work in construction, manufacturing, and repair industries.

- Work or technical experience and a high school diploma are preferred by employers.

- Welding certification can demonstrate competence and improve job prospects.

- Courses in blueprint reading, mechanical drawing, physics, chemistry, and metallurgy can be beneficial for aspiring welders.

- Welding apprenticeships can be a starting point for those interested in the trade.

- Welding offers a career change option for those seeking a different path.

- Anyone can learn welding skills with enthusiasm and effort.

- Welding provides diverse career paths and opportunities for growth.

- Mathematical skills are crucial for reading blueprints and calculating welding proportions.

- Precision cutting and attention to detail are essential for accurate welding.

- Good vision, physical endurance, and hand-eye coordination are important physical capabilities for welders.

- Educational skills, including understanding mathematics and physics, are necessary for the profession.

- Welders need to comprehend welding theory and material properties to produce exceptional welds.

- Being self-motivated, dependable, and efficient in organizing tasks are vital personal skills.

- Time management and clear communication contribute to a welder's success.

- Welders must be familiar with various technological tools and equipment.

- Knowledge of different welding techniques like MIG, TIG, and stick welding increases marketability.

- Learning additional fabrication tasks enhances a welder's adaptability and value.

- Physical strength and endurance are essential due to the demanding nature of the job.

- Good work ethics and dedication are crucial for success in welding.

- Teamwork and communication skills are vital for working on welding projects as part of a larger team.

- Skilled welders undergo apprenticeships, possess metal knowledge, and can work independently.

- Unskilled welders have limited training and may assist skilled welders.

- Skilled welders can diagnose and fix welding problems, while unskilled welders perform basic tasks.

- Different welding jobs have varying training requirements.

- Understanding the distinction between skilled and unskilled welders helps in career planning.

- Welding plays a crucial role in manufacturing ships, cars, planes, and buildings.

- Welders can repair metal by filling holes, cracks, and dents.

- Employers prefer candidates with some work experience and a high school diploma.

- A certificate or degree can be advantageous for welders' resumes.

- Welders should study physics, chemistry, metallurgy, and related subjects for a better understanding of materials.

- Welders must have good mathematical skills to read blueprints and calculate dimensions accurately.

- Paying attention to detail is critical, especially when working on projects that affect public safety.

- Welders should be physically fit to handle the job's demands and maintain a steady hand.

- Reading and interpreting drawings are necessary for understanding project requirements.

- Teamwork and effective communication are essential for working well with others on welding projects.

- Possessing technological skills and knowing how to use tools correctly are vital for welders.

- Learning different welding techniques can broaden a welder's career opportunities.

- Constantly developing skills and staying adaptable sets welders apart from the competition.

- Welding requires physical endurance and mental toughness, especially in challenging conditions.

- Having a strong work ethic is crucial for a welder's professional standing and industry reputation.

- Welding projects are part of a larger whole, emphasizing the importance of teamwork.

- Understanding the requirements of skilled and unskilled welders helps determine appropriate training for entering the field.

Frequently Asked Questions

Welding necessitates a range of primary skills for success, encompassing technical expertise, encompassing proficiency in various welding techniques and equipment. Safety awareness is crucial to mitigate risks, while problem-solving abilities enable welders to tackle challenges. Effective communication skills facilitate collaboration, while physical fitness ensures endurance during physically demanding tasks.

Safety knowledge is paramount in welding as it safeguards welders from potential hazards, mitigates the risk of accidents, and establishes a secure working environment. By adhering to proper safety practices, welders can minimise occupational hazards and prioritise their well-being while executing welding tasks.

Hand-eye coordination plays a vital role in welding as it empowers welders to manipulate welding tools with precision, ensuring accurate deposition of welds. Synchronising hand movements with visual perception is essential for achieving the desired weld quality and overall welding proficiency.

Critical thinking is integral to welding, enabling welders to skillfully analyse intricate situations, assess potential solutions, and make well-informed decisions. By employing critical thinking skills, welders can effectively navigate challenges, optimise welding processes, and consistently achieve desired results.

Maintaining professionalism is of utmost importance in the field of welding. It fosters trust and credibility among clients and colleagues, ensures adherence to ethical standards, and contributes to a positive reputation within the industry.