Regarding the complex world of metal fabrication, the brake press is a fundamental component that allows precision and variety. This powerful machine, which is required for bending sheet and plate metal, plays a crucial role in producing a wide variety of components across various industries, including the aerospace industry, the automobile industry, and more.

However, the actual potential of a brake press is not only unlocked by the machine's mechanical capabilities but also by the trained persons who run the machine. Using this blog, we dig into the world of brake press operators, the unsung artisans of the metalworking business.

During this discussion, we will investigate who they are, the abilities and information they possess, and the crucial part they play in transforming raw metal into components that are accurate enough to fulfil the stringent requirements of today's industrial demands. We invite you to join us as we shed light on the expertise behind the machine, underlining the significance of the human touch in this age of automation.

The Role Of A Brake Press Operator

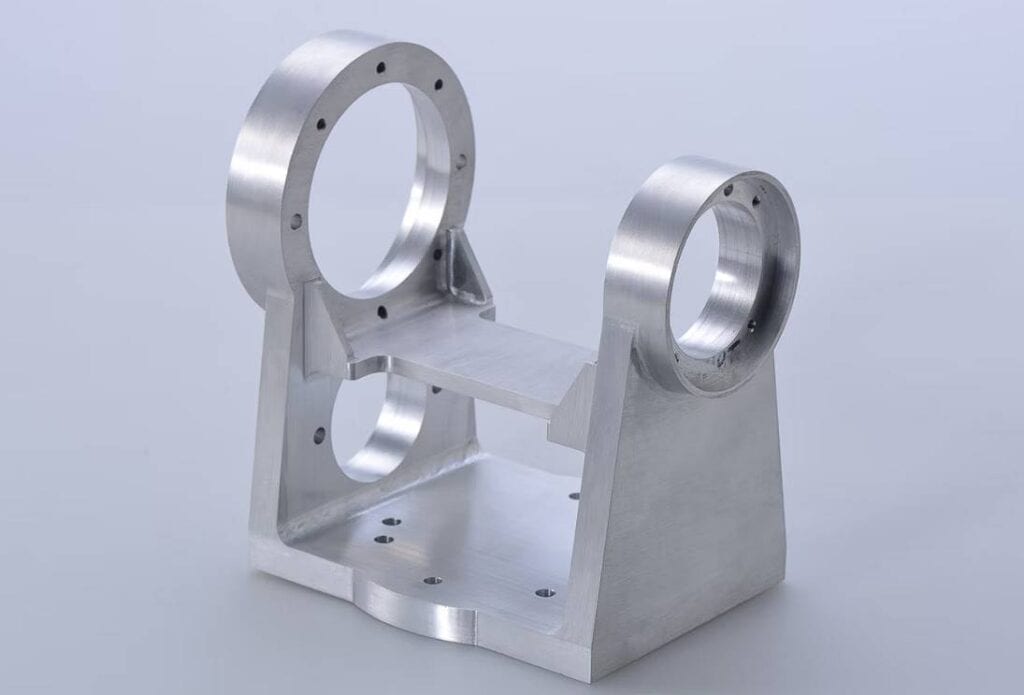

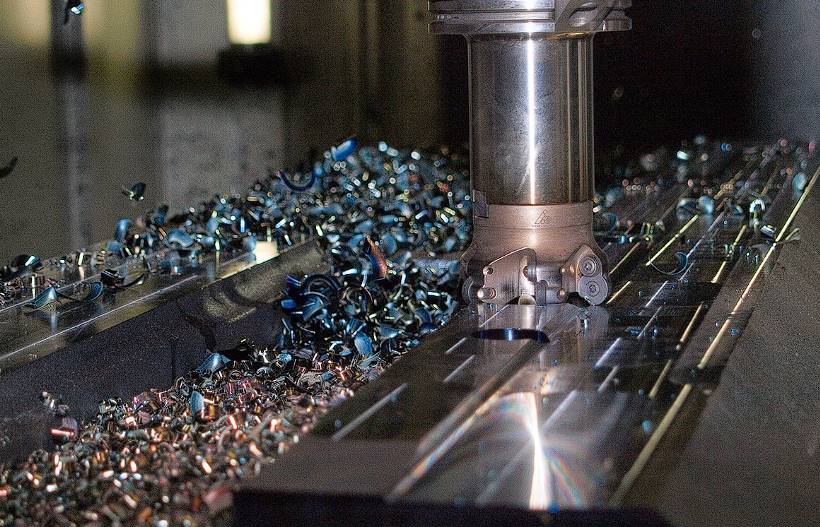

In the dynamic manufacturing world, the Brake Press Operator stands out as a pivotal role, essential for precisely shaping and fabricating metal components. This skilled position involves operating a press brake, a computer-controlled (CNC) machine that plays a critical role in bending, cutting, and shaping metal sheets into various parts and tools used across numerous industries.

Key Responsibilities:

Machine Operation and Setup: Brake press operators are responsible for setting up the press brake machine and ensuring it's calibrated and ready for the task. This includes selecting, positioning, and securing the appropriate tools and dies for the job.

Blueprint Interpretation: A significant part of their role involves reading and interpreting engineering drawings and blueprints to understand the fabricated piece's specifications. This knowledge allows them to adjust the machine settings accurately to achieve the desired bends and cuts.

Quality Assurance: Operators regularly inspect the fabricated components to ensure they meet stringent quality standards. This might involve measuring the pieces and making necessary adjustments to the machine to correct any discrepancies.

Maintenance and Safety: Routine maintenance of the press brake machine is crucial to prevent downtime and ensure operational safety. Operators are tasked with keeping the machine in optimal condition, alongside adhering to all health and safety regulations to maintain a safe working environment.

Skills And Qualifications:

A high school diploma or equivalent, often supplemented by technical training or apprenticeships in metal fabrication.

Strong mathematical skills for precise measurements.

Mechanical aptitude and problem-solving skills.

Proficiency in reading and interpreting technical drawings and blueprints.

Experience with CNC machinery is highly valued, as is a keen eye for detail to ensure the quality of the final product.

Career Path And Salary:

The path to becoming a proficient Brake Press Operator can vary, with individuals often starting in entry-level positions and gaining experience through on-the-job training and technical education. Certification in CNC operations or metal fabrication can enhance job prospects. Salaries for Brake Press Operators can vary significantly based on experience, location, and the complexity of the work, with the median wage in Canada being around $21.16 per hour.

The Impact Of Brake Press Operators:

Brake Press Operators play a crucial role in manufacturing, contributing to creating components integral to various products and structures. Their expertise ensures that parts are made to exact specifications, which is vital for the overall quality and functionality of the final products. As the manufacturing sector continues to evolve with technological advancements, the demand for skilled Brake Press Operators remains high, reflecting the importance of this role in today's industrial landscape.

Skills And Qualifications

Brake Press Operators are pivotal in the manufacturing industry, where precision and skill translate directly into the quality of the final product. These professionals operate press brake machines, which bend, cut, and shape metal sheets into components used across various industries, including automotive, aerospace, and construction. The role demands technical knowledge, practical skills, and personal attributes to ensure operational efficiency and product quality.

Technical Skills And Knowledge:

- Machine Operation and Setup: Proficiency in operating CNC (Computer Numerically Controlled) press brakes and setting them up based on job requirements is fundamental. Operators must adjust machine settings to achieve desired bends and shapes, adhering to precise specifications.

- Blueprint Reading: The ability to interpret engineering drawings and blueprints is crucial. This skill ensures that the parts manufactured meet the design requirements, including dimensions and tolerances.

- Measurement and Inspection: Knowledge of using measuring tools like callipers, micrometres, and tape measures is essential for quality control. Operators must inspect the parts produced to ensure they meet the strict quality standards.

- Material Knowledge: Understanding the properties of different metals, such as steel, aluminium, and copper, allows operators to adjust machine settings appropriately and predict how materials will behave during the bending process.

- Maintenance and Troubleshooting: The press brake machine must be maintained regularly to keep it in optimal condition. Operators should also be able to troubleshoot and resolve common machine issues to minimise downtime.

Soft Skills:

- Attention to Detail: Precision is key in brake press operation. A keen eye for detail ensures that each part produced matches the specifications exactly, minimising waste and rework.

- Problem-Solving: It is valuable to quickly identify and solve problems during the manufacturing process. This skill helps maintain productivity and meet production deadlines.

- Communication: Effective communication with team members and supervisors is essential for coordinating tasks, reporting issues, and ensuring a smooth workflow.

- Safety Awareness: Operators must be firmly committed to safety protocols to protect themselves and their colleagues from potential hazards associated with machine operation.

- Adaptability: The manufacturing environment is dynamic, with frequent changes in production schedules and job requirements. Being adaptable allows operators to switch tasks or adjust to new processes efficiently.

Qualifications:

A high school diploma is typically the minimum educational requirement, with additional vocational training or certifications in machine operation or metal fabrication being highly beneficial.

Employers often prefer experience with CNC machinery and metal fabrication processes.

Certifications related to safety, machine operation, or specific press brake models can enhance a candidate's job prospects.

Career Development:

Continuous learning through on-the-job experience, technical courses, and certification programs can lead to advancements in roles such as machine setup technician, supervisor or even into roles focused on CNC programming and design.

Participation in apprenticeships or mentorship programs can provide hands-on experience and industry insights, facilitating career growth and skill enhancement.

Career Path And Opportunities

The role of a Brake Press Operator is pivotal in the manufacturing and metal fabrication industries, where precision and skill translate directly into the quality and functionality of the final products. This career offers a unique blend of technical challenges and rewards, making it an attractive option for those interested in working with advanced machinery and contributing to creating a wide range of metal products.

Starting Point And Growth:

Brake Press Operators typically begin their careers with a high school diploma or equivalent, often supplemented by vocational training in machine operation or a related field. The journey starts at an entry-level position, where operators gain hands-on experience under the guidance of seasoned professionals. This period is crucial for mastering the intricacies of press brake machinery, understanding safety protocols, and developing the ability to read and interpret blueprints accurately.

Advancement Opportunities:

With experience, Brake Press Operators can advance to supervisory roles, quality assurance, or even move into business development positions within the industry. Many companies prefer to promote from within, recognising the value of experienced operators who understand the company's processes and standards.

This career path offers the potential for significant professional growth, with opportunities to transition into roles that involve greater responsibility, including overseeing production lines, managing teams, or contributing to the strategic planning of manufacturing processes.

Competitive Compensation:

The manufacturing sector is known for offering competitive compensation packages, including above-average pay rates, comprehensive benefits, and opportunities for overtime work. The salary of a Brake Press Operator can vary based on factors such as geographic location, experience level, and the specific industry sector. However, it consistently offers a stable and rewarding income.

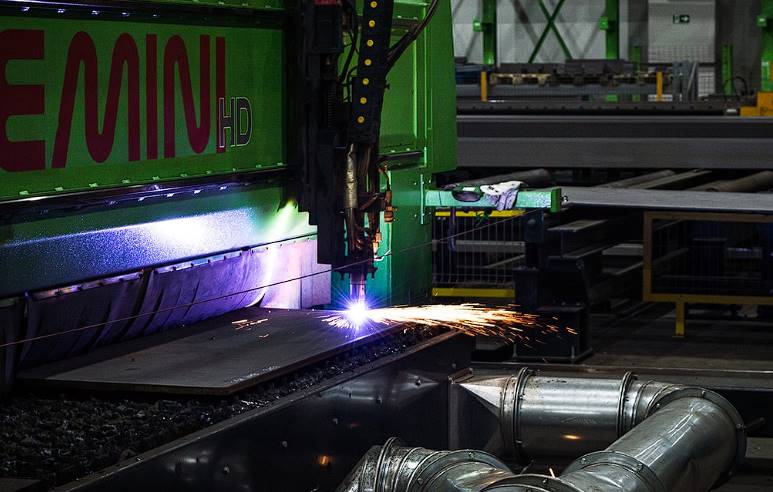

Technological Advancements:

The metal fabrication field is at the forefront of technological innovation, incorporating advanced computer numerical control (CNC) technology, automation, and robotics into daily operations. Brake Press Operators have the opportunity to work with cutting-edge machinery, staying ahead of technological trends and continuously expanding their skill set. This aspect of the job is particularly appealing to tech-savvy individuals who enjoy working in dynamic, evolving environments.

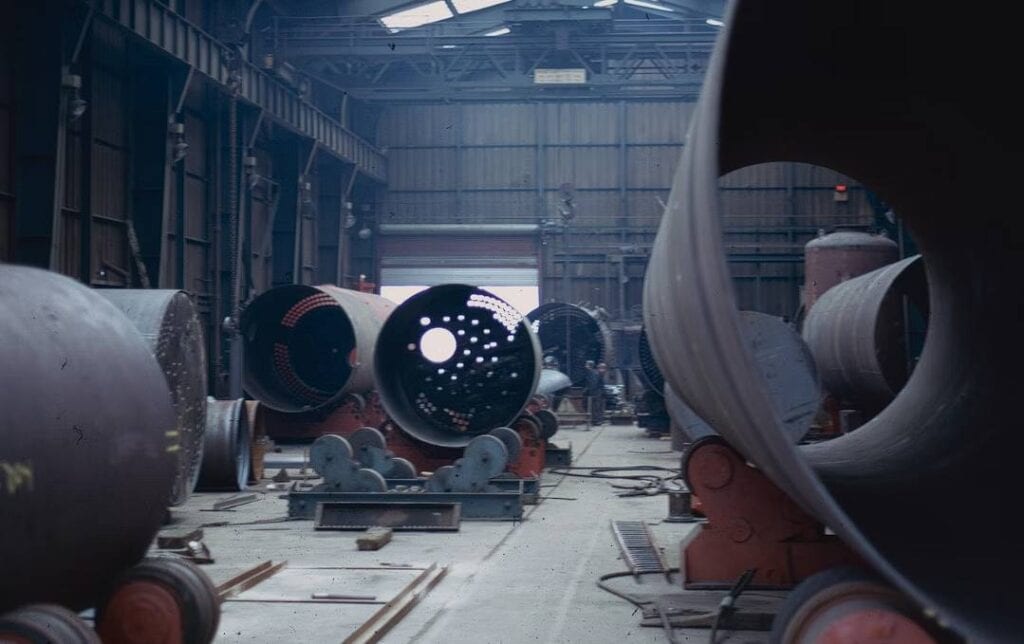

Impact On The Economy And Society:

Manufacturing is a critical component of the national economy, and Brake Press Operators play a direct role in sustaining the industry's growth and innovation. By producing high-quality metal components used in various sectors, including automotive, aerospace, construction, and consumer goods, operators contribute to developing infrastructure, transportation, and technology. This career offers the satisfaction of knowing that one's work has a tangible impact on society and the economy.

Conclusion

Brake Press Operators are essential in the manufacturing industry, playing a pivotal role in precisely shaping and fabricating metal components. They operate a computer numerically controlled (CNC) press brake machine, which is crucial for bending, cutting, and shaping metal sheets into various parts and tools. Their responsibilities include machine operation and setup, blueprint interpretation, quality assurance, and maintenance and safety.

Career paths for Brake Press Operators can vary, with entry-level positions often starting with on-the-job training and technical education. Certification in CNC operations or metal fabrication can enhance job prospects. Salaries can vary significantly based on experience, location, and the complexity of the work.

The impact of Brake Press Operators is significant. Their expertise ensures parts are made to exact specifications, which is vital for the overall quality and functionality of the final products. As the manufacturing sector evolves with technological advancements, the demand for skilled Brake Press Operators remains high, reflecting the importance of this role in today's industrial landscape.

Brake Press Operators are crucial in manufacturing and operating press brake machines that bend, cut, and shape metal sheets into components used across various industries. Their technical skills include machine operation and setup, blueprint reading, measurement and inspection, material knowledge, maintenance and troubleshooting, and soft skills like attention to detail, problem-solving, communication, safety awareness, and adaptability.

Continuous learning through on-the-job experience, technical courses, and certification programs can lead to advancements in roles such as machine setup technician, supervisor or even into roles focused on CNC programming and design.

The career path for Brake Press Operators is unique, offering a blend of technical challenges and rewards. They typically begin their careers with a high school diploma or equivalent, often supplemented by vocational training in machine operation or a related field. With experience, they can advance to supervisory roles, quality assurance, or business development positions within the industry.

The manufacturing sector offers competitive compensation packages, including above-average pay rates, comprehensive benefits, and overtime opportunities. The metal fabrication field is at the forefront of technological innovation, incorporating advanced computer numerical control (CNC) technology, automation, and robotics into daily operations.

Brake Press Operators contribute to developing infrastructure, transportation, and technology, contributing to the economy and society.

Content Summary

- Brake press operators are essential in the metal fabrication industry, enabling precision and variety in manufacturing.

- These skilled workers operate machines crucial for bending and shaping metal for various industries, including aerospace and automotive.

- The true potential of a brake press is unlocked by the operators, who are the artisans behind the machine.

- This blog explores the world of brake press operators, highlighting their skills, knowledge, and importance.

- Brake Press Operators are key in manufacturing and precisely shaping metal components.

- They operate computer numerically controlled (CNC) machines, which are crucial for various industries' parts and tools.

- Their responsibilities include machine setup, blueprint interpretation, quality assurance, and maintenance.

- Operators ensure the press brake machine is calibrated and ready, selecting appropriate tools and dies.

- They read and interpret engineering drawings to adjust machine settings for desired outcomes.

- Regular inspections by operators ensure components meet stringent quality standards.

- Maintenance of the press brake machine is vital for operational safety and preventing downtime.

- Qualifications include a high school diploma, technical training, and strong mathematical and mechanical skills.

- This profession highly values experience with CNC machinery and a keen eye for detail.

- The career path for Brake Press Operators varies, with opportunities for advancement through experience and certification.

- Salaries can significantly vary, with the median wage in Canada around $21.16 per hour.

- Operators contribute to creating components integral to various products, ensuring parts meet exact specifications.

- The demand for skilled Brake Press Operators remains high, reflecting their importance in the industrial landscape.

- Technical knowledge and practical skills are required to operate press brake machines efficiently.

- Proficiency in machine operation, blueprint reading, and material knowledge is fundamental.

- Soft skills like attention to detail, problem-solving, and communication are crucial for success.

- Qualifications often include vocational training and experience with CNC machinery.

- Continuous learning and apprenticeships can lead to career advancements in the field.

- Individuals can grow into supervisory or specialised roles, starting as entry-level operators.

- The manufacturing sector offers competitive compensation and opportunities for professional growth.

- Technological advancements in metal fabrication allow operators to work with cutting-edge machinery.

- Brake Press Operators significantly impact the economy and society by producing essential metal components.

- Their work contributes to developing infrastructure, transportation, and technology across sectors.

- The role of a Brake Press Operator combines technical challenges with rewarding outcomes.

- Operators are pivotal in transforming raw metal into precise components for industrial use.

- Their expertise ensures the functionality and quality of the final products in various industries.

- The profession offers a stable career with advancement paths within the manufacturing industry.

- Operators are involved in a dynamic environment, adapting to new processes and production schedules.

- Safety awareness is key to the job, with operators following protocols to prevent hazards.

- The job requires a blend of technical knowledge, from machine operation to understanding metal properties.

- Operators play a crucial role in quality control, inspecting parts to meet strict standards.

- The career offers access to the forefront of technological innovation in metal fabrication.

- Advancements in CNC technology and automation enhance the precision and efficiency of manufacturing processes.

- The profession is appealing to individuals interested in technology and innovation.

- Operators' work directly impacts the quality of life by contributing to national success.

- The manufacturing sector's growth offers numerous opportunities for skilled Brake Press Operators.

- The profession is recognised for contributing to the economy and the manufacturing industry's innovation.

- Operators' skills and qualifications are crucial for meeting today's industrial demands.

- The role requires a commitment to continuous improvement and skill enhancement.

- Certification in CNC operations or metal fabrication can open doors to higher job prospects.

- A high demand marks the profession for skilled individuals capable of operating advanced machinery.

- Brake Press Operators are at the heart of the manufacturing process, ensuring precision in metal fabrication.

- Their role is critical in maintaining the operational efficiency and safety of the press brake machine.

- The career path offers a rewarding journey from entry-level positions to roles with greater responsibility.

- The profession underscores the importance of human skill and expertise in an age of automation.

- Brake Press Operators are the unsung artisans behind the scenes, shaping the future of manufacturing with precision and dedication.

Frequently Asked Questions

A brake press operator is a skilled technician who operates a press brake machine, which is used for bending and shaping metal sheets and plates. These operators play a crucial role in manufacturing and producing components for various aerospace, automotive, and construction industries.

A high school diploma or equivalent is typically required to become a brake press operator. Additional vocational training or apprenticeships in metal fabrication and experience with CNC (Computer Numerically Controlled) machinery can enhance job prospects. Strong mathematical skills, mechanical aptitude, and the ability to read technical drawings are also necessary.

Brake press operators need a combination of technical and soft skills, including:

Proficiency in operating CNC press brakes and setting them up according to job requirements.

The ability to read and interpret engineering drawings and blueprints.

Knowledge of using measuring tools like callipers and micrometres for quality control.

Attention to detail, problem-solving abilities, effective communication, safety awareness, and adaptability.

The primary responsibilities include machine operation and setup, blueprint interpretation, quality assurance through regular inspections, and maintenance and safety of the press brake machine. Operators ensure the machine is calibrated, select the appropriate tools and dies, and adjust settings to achieve the desired bends and cuts.

Advancement can come through gaining experience, on-the-job training, and technical education. Certifications in CNC operations or metal fabrication can further enhance career prospects. With time, operators can move into supervisory roles, quality assurance, or positions focused on CNC programming and design.